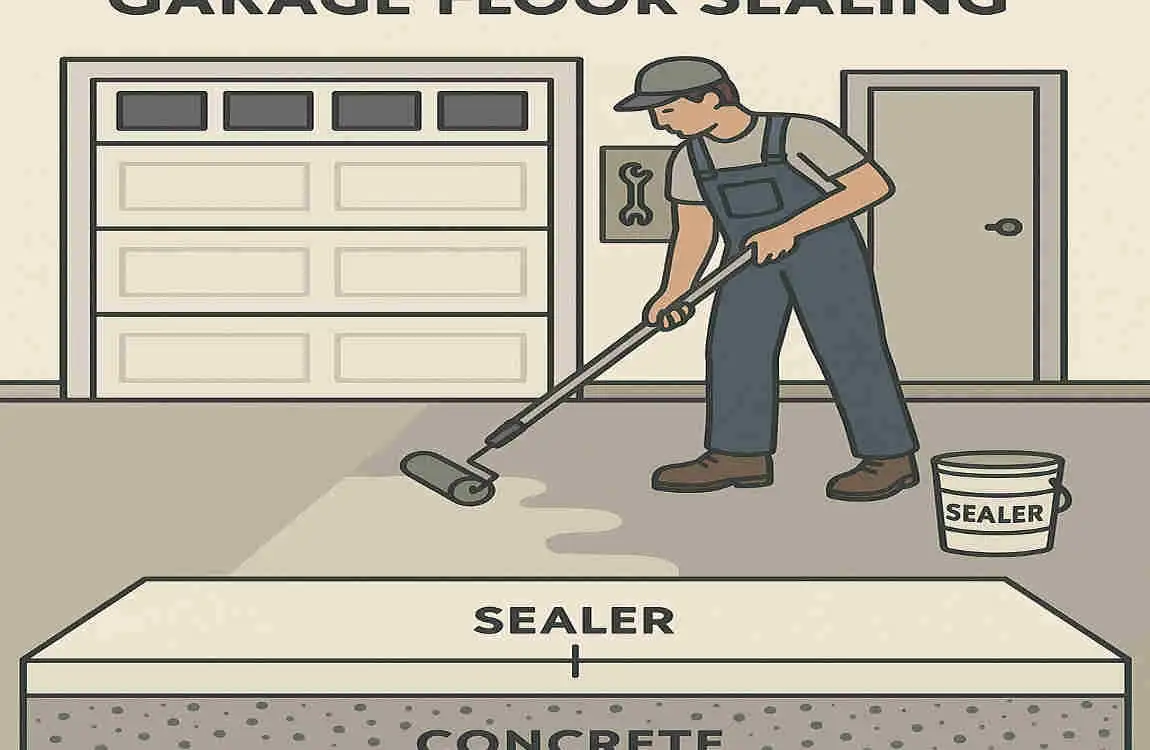

Sealing your home garage floor might not be the first thing on your to-do list, but if you’re looking for durability, cleanliness, and long-term protection, it’s an essential home improvement project. This step-by-step guide will walk you through everything you need to know about how to seal a home garage floor, from preparation to maintenance, ensuring your floor not only looks great but lasts for years to come.

Understanding Garage Floor Sealing

What Does Sealing a Garage Floor Mean?

Sealing a garage floor involves applying a protective coating that adheres to the concrete surface, creating a shield against external elements. This process not only protects the floor but also makes it easier to clean and maintain.

Why Is It Necessary?

Concrete floors are porous, meaning they can absorb liquids like oil, water, and chemicals. Over time, this can lead to discoloration, cracking, and even structural damage. Sealing fills these pores, creating a non-porous surface that’s resistant to stains, moisture, and wear.

Types of Garage Floor Sealers

There are several types of sealers available, each with unique benefits. Here’s a quick comparison:

Type of Sealer Key Features Pros Cons

Acrylic Sealer: Quick-drying; creates a thin protective film. Easy to apply, affordable. Less durable, requires frequent reapplication.

Epoxy Sealer: Thick, durable, and chemical-resistant coating. Long-lasting, highly durable. Requires precise application, can be expensive.

Polyurethane Sealer is Resistant to scratches and UV rays. Excellent durability, glossy finish. Longer drying time, costly

Penetrating Sealer Absorbs into the concrete for deep protection. Long-lasting, protects from within. Does not enhance surface appearance.

Each type of sealer has its pros and cons, so choosing the right one depends on your specific needs, budget, and desired level of protection.

Preparing Your Garage Floor for Sealing

Preparation is the most critical step for successful sealing. Skipping or rushing this stage can lead to uneven application, peeling, or poor adhesion.

Step-by-Step Preparation Process

- Clear the Garage

- Remove all items, including cars, tools, and storage units. Sweep or vacuum the floor to eliminate dirt and debris.

- Clean the Surface

- Use a degreaser to remove oil stains, then pressure-wash the floor to deep-clean it. Pay extra attention to areas with visible stains or residue.

- Repair Cracks and Imperfections

- Inspect the floor for cracks, holes, or uneven surfaces. Use a concrete filler or epoxy patching compound to repair these issues.

- Check for Moisture

- Perform a simple water droplet test: sprinkle water on different sections of the floor. If the water beads up, the surface is dry and ready. If it absorbs, there’s too much moisture, and sealing should be postponed.

- Etch the Surface (If Necessary)

- For smooth concrete, use an etching solution to create a rough texture. This helps the sealant adhere better to the surface.

Ideal Weather Conditions for Sealing

Sealing works best in dry conditions with moderate temperatures (50-90°F). Avoid sealing during high humidity or rainy days, as excess moisture can interfere with the curing process.

Step-by-Step Guide: How to Seal a Home Garage Floor

Once your surface is prepped, it’s time to start sealing! Here’s a practical, step-by-step guide:

Materials You’ll Need

- Garage floor sealant (choose based on your needs)

- Paint rollers, brushes, or sprayers

- Protective gear (gloves, goggles, mask)

- Concrete etching solution (if needed)

- Cleaning supplies (degreaser, pressure washer)

- Painter’s tape (to protect walls or edges)

Instructions

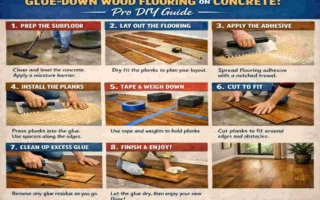

- Remove Old Coatings

- If your garage floor has previous sealant or paint, strip it using a chemical remover or a grinding tool.

- Etch the Concrete

- Apply an etching solution to open the concrete’s pores, improving the sealant’s adhesion. Rinse thoroughly and let the floor dry completely.

- Apply the First Coat

- Using a roller or sprayer, apply the sealant evenly across the floor. Start at the back and work your way toward the exit. Avoid over-application to prevent puddling.

- Let it Dry

- Allow the first coat to dry per the manufacturer’s instructions (usually 24-48 hours).

- Apply a Second Coat

- For best results, apply a second coat in the opposite direction of the first. This ensures uniform coverage and extra protection.

- Optional: Apply a Topcoat

- For added shine and durability, consider applying a protective topcoat or floor wax.

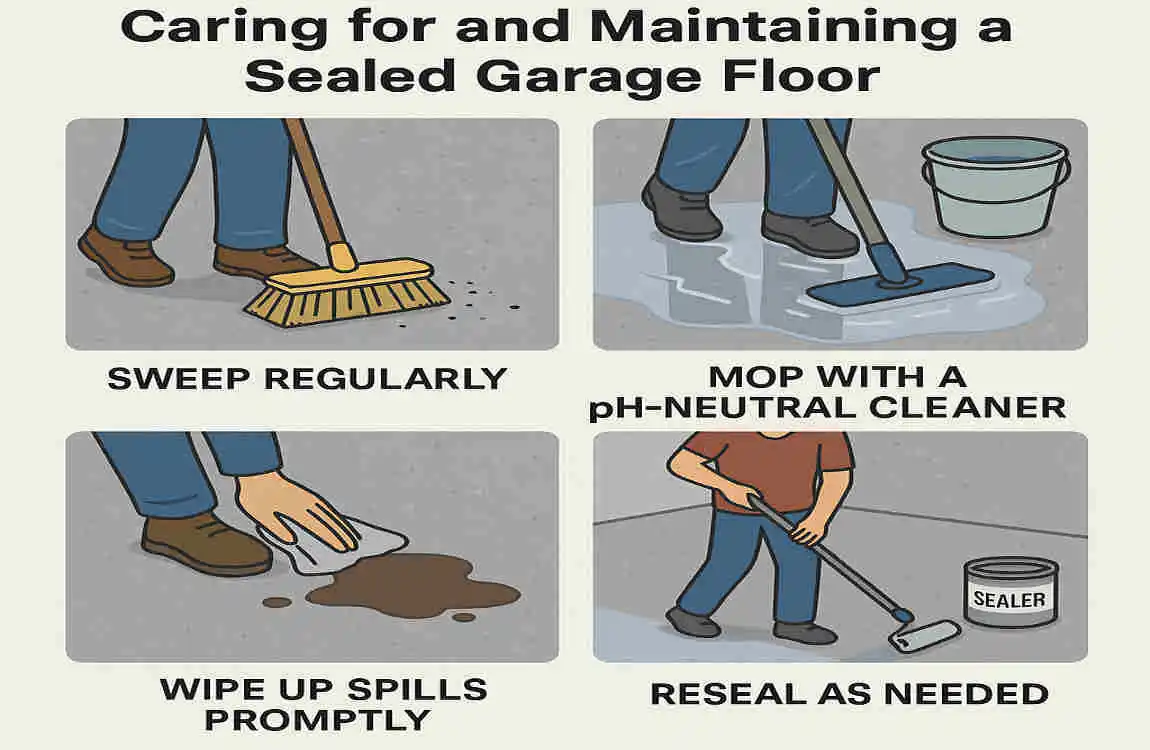

Caring for and Maintaining a Sealed Garage Floor

A sealed garage floor is low maintenance, but regular care can prolong its lifespan.

Cleaning Tips

- Use Mild Cleaners: Regularly mop with a pH-neutral cleaner to prevent damage to the sealant.

- Avoid Abrasives: Do not use harsh chemicals, steel wool, or abrasive tools that can scratch the surface.

- Spot Clean Stains: For oil or chemical spills, clean immediately with a degreaser.

When to Reseal

Over time, your sealant may wear down. Signs that it’s time to reseal include:

- Dull or faded appearance

- Water no longer beading on the surface.

- Visible wear or peeling

Most garage floors need resealing every 2-5 years, depending on usage and the type of sealant applied.

Troubleshooting Common Issues

Even with proper application, issues can arise. Here’s how to address them:

- Peeling or Bubbling Sealant: This often occurs due to improper surface preparation or moisture. Strip the affected area, re-clean, and reapply the sealant.

- Stubborn Stains: For tough spots, use a poultice or specialized stain remover.

- Uneven Coating: Sand down uneven areas, then apply a thin additional coat to smooth them out.

Benefits of a Sealed Garage Floor

Sealing your garage floor offers numerous benefits, including:

- Long-Term Protection: Shields against cracks, stains, and moisture.

- Improved Aesthetics: Creates a polished, professional look.

- Easier Maintenance: Non-porous surfaces are easier to clean and maintain.

- Increased Property Value: A well-maintained garage can boost your home’s resale value.

How to Seal a Home Garage Floor: FAQ

Why should I seal my garage floor?

Sealing your garage floor provides several benefits:

- Protection from damage: It prevents cracks, stains, and moisture from penetrating the concrete.

- Easier cleaning: A sealed floor is non-porous, making it resistant to oil, grease, and chemical spills.

- Improved durability: Sealing extends your garage floor’s lifespan by protecting it from wear and tear.

- Enhanced aesthetics: A sealed floor looks polished and professional, improving the overall appearance of your garage.

What types of sealers are available for garage floors?

There are four main types of garage floor sealers:

- Acrylic sealers: Affordable and easy to apply, but less durable and may require frequent reapplication.

- Epoxy sealers: Highly durable and resistant to chemicals, making them ideal for heavy-duty use.

- Polyurethane sealers: Scratch-resistant and UV-stable, offering excellent durability and a glossy finish.

- Penetrating sealers: Absorb into the concrete for deep protection without altering the surface appearance.

How do I prepare my garage floor for sealing?

Preparation is key to a successful sealing job. Follow these steps:

- Clear the garage: Remove all items, including vehicles, tools, and storage units.

- Clean the floor: Sweep away debris, degrease oil stains, and pressure-wash the surface.

- Repair cracks: Use a concrete filler or polyurethane crack filler to fix any imperfections.

- Check for moisture: Perform a water-droplet test to ensure the floor is sufficiently dry for sealing.

- Etch the surface: If the concrete is smooth, use an etching solution to create a rough texture for better adhesion.

What tools and materials do I need to seal my garage floor?

Here’s a list of essential tools and materials:

- Garage floor sealer (choose based on your needs)

- Paint rollers, brushes, or sprayers

- Protective gear (gloves, goggles, mask)

- Concrete etching solution (if needed)

- Degreaser and cleaning supplies

- Painter’s tape to protect walls and edges.

Can I seal my garage floor in any weather?

No, weather conditions play a significant role in the sealing process. Most sealers require temperatures between 50°F and 90°F for proper application and curing. Avoid sealing during high humidity or rainy days, as moisture can interfere with the sealant’s adhesion and drying process.