You have finally decided to upgrade your home or shed with a sleek, durable metal roof. You’ve got the panels delivered, the sun is shining, and you are ready to get to work. But then, you stare at that first sheet of corrugated steel and realise something terrifying—you aren’t exactly sure how to cut metal roofing without mangling it, hurting yourself, or voiding the warranty.

If that sounds familiar, take a deep breath. You are definitely not alone. Millions of homeowners decide to tackle DIY roofing projects every single year because of the incredible cost savings and the satisfaction of doing it yourself. Metal roofing is exploding in popularity because it lasts for decades and looks fantastic. However, it does come with a unique set of challenges. Unlike wood or shingles, metal bites back. It can leave jagged edges, create hot sparks, and warp if you look at it the wrong way.

Why Cutting Metal Roofing Requires the Right Approach

Before we jump straight into the power tools, we need to pause and talk about the material itself. If you are used to working with asphalt shingles or timber, you have to shift your mindset. Metal roofing is a completely different beast.

Metal panels, usually made of steel or aluminium, are generally thin gauge. This implies they are strong, but they are also prone to bending and kinking if you aren’t careful. When you cut wood, you are removing material in the form of sawdust. When you cut metal, you are essentially shearing or grinding through a hardened surface.

The Risks of Getting It Wrong

If you rush into this without understanding how to cut metal roofing correctly, three things usually happen:

- Personal Injury: Freshly cut metal is sharper than a surgical scalpel. One slip without the right gear can lead to a serious emergency room visit.

- Compromised Longevity: If you use a tool that generates too much heat (like an abrasive blade), you can burn off the protective coating (Galvalume or paint). This invites rust before the roof is even installed.

- Ugly Aesthetics: Using the wrong blade or technique results in jagged, wavy edges that look unprofessional and don’t seal properly against weather stripping.

The Benefits of Pro Techniques

On the flip side, when you use the proper methods we are about to discuss, you get clean, straight cuts every time. This ensures your seams are tight, your roof is waterproof, and the material remains corrosion-resistant. Plus, knowing the right way to do it speeds up the installation process significantly.

To help you understand what you are up against, here is a quick breakdown of roofing types and the general approach for each:

Metal Roofing Type Characteristics Best Cutting Approach

Corrugated Panels Wavy pattern, exposed fasteners. Needs a tool that rides over bumps easily (Nibblers/Shears).

Standing Seam Flat panels with raised locking edges. Precision cutting is key; use shears for straight lines.

Stone Coated Metal with a granule coating. Requires a specialised guillotine or circular saw to prevent crushing.

R-Panel heavy-duty, high ribs. Power shears or a circular saw with a cold-cutting blade.

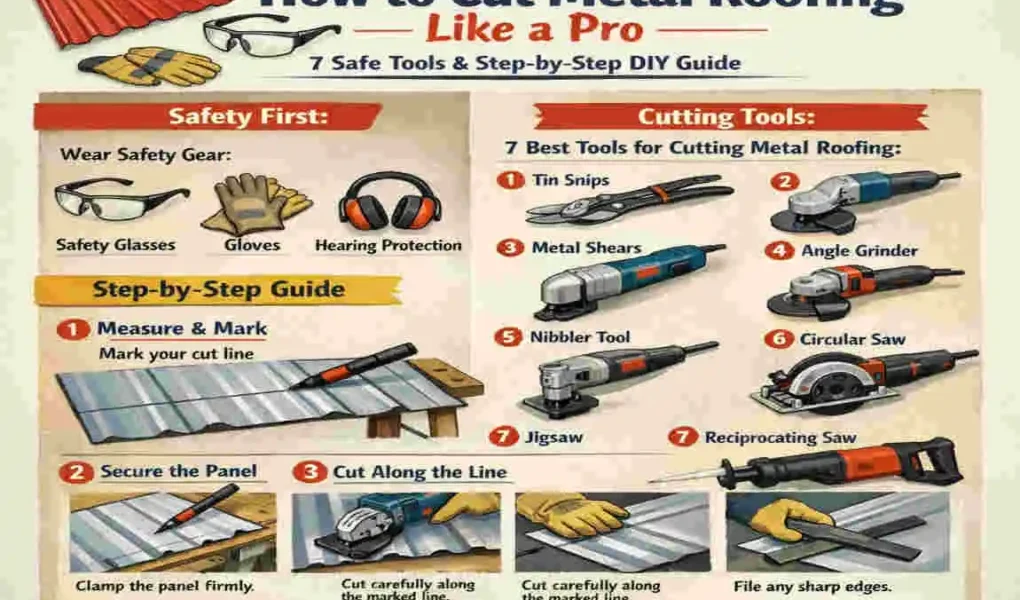

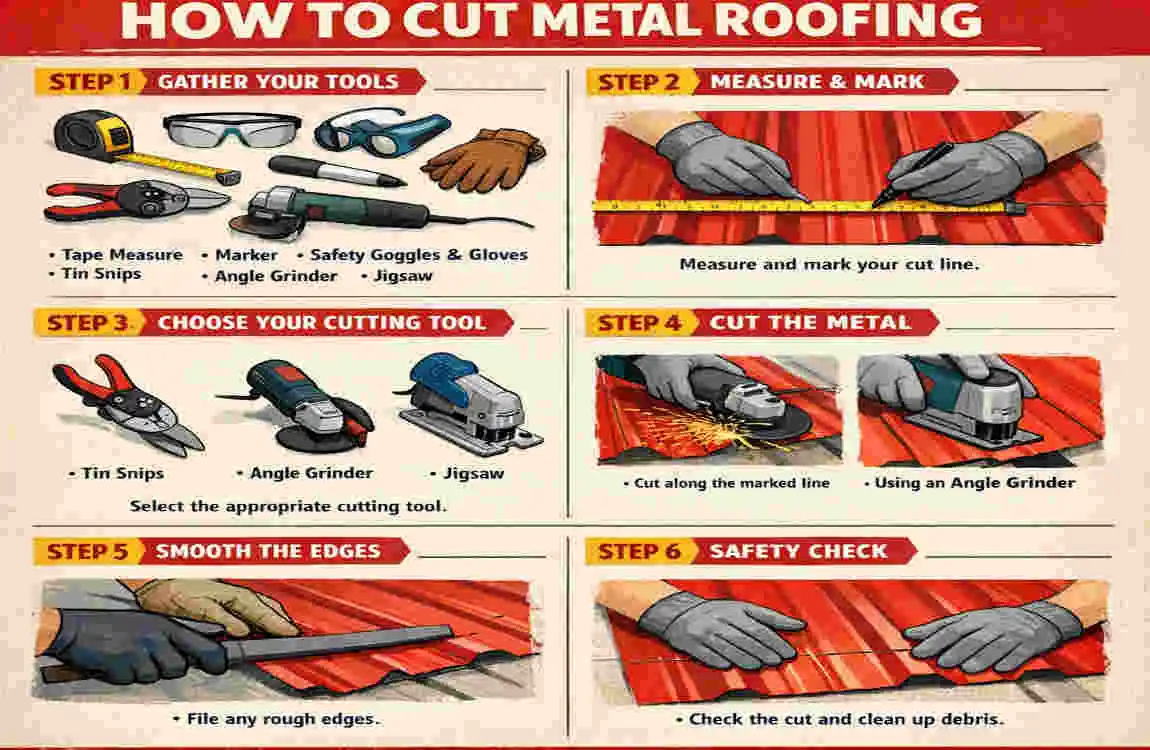

7 Safe Tools for Cutting Metal Roofing Like a Pro

Choosing the right tools is the absolute key to safe, precise cuts. You cannot just grab whatever saw is in the garage and hope for the best. Different cuts require different tools. Below, we break down the 7 best options for DIYers learning how to cut metal roofing.

Metal Roofing Shears (Electric Nibblers)

If you are going to invest in one tool specifically for this job, let it be electric metal roofing shears. Often called double-cut shears, these are the gold standard for professional roofers.

Why They Rock: These tools are designed to remove a thin strip of metal (about 1/4 inch wide) as they cut. Because they take that strip out, the metal doesn’t warp or bend on either side of the cut. They leave a perfectly smooth edge that is generally free of burrs.

Best For: Long, straight cuts on corrugated or ribbed panels. They can handle the “hills and valleys” of the metal profile without getting stuck.

The Downside: They can be a bit pricey, ranging from $50 to $150 depending on the brand (Malco and DeWalt are popular choices). They also aren’t great for tight curves. However, for the bulk of your long cuts, this tool is unbeatable.

Tin Snips (Straight & Aviation)

Sometimes, the old ways are the best ways. You cannot complete a metal roofing job without a good pair of tin snips in your tool belt.

Understanding the Handles: You will notice tin snips come with different colored handles, and this isn’t for decoration.

- Red Handles: These are designed to cut curves to the left.

- Green Handles: These cut curves to the right.

- Yellow Handles: These are for straight lines.

Best For: Tin snips are essential for small, detailed work. When you need to notch out a corner to fit around a vent pipe or trim off a tiny sliver at the end of a run, power tools are too clumsy. Snips give you total control.

Nibbler Attachment for Drills

If you already own a good power drill (and you likely do), a nibbler attachment is a fantastic, budget-friendly “hack.”

How It Works: This attachment fits into the chuck of your drill. It uses a punch-and-die mechanism to “nibble” away small half-moon shapes of metal. It turns your standard drill into a powered metal cutter.

Best For: This is incredible for cutting circles or odd shapes, like holes for plumbing vents. It is also very manoeuvrable, allowing you to turn tight corners that shears can’t handle.

The Catch: It creates a mess. Those little half-moon metal chips (swarf) fall everywhere. You must sweep these off the roof immediately, or they will rust and stain your beautiful new panels.

Circular Saw with a Non-Ferrous Metal Blade

For speed and long rips, many DIYers turn to their trusty circular saw. However, you cannot just use a wood blade, and you should avoid abrasive blades if possible.

The Right Setup: You need a carbide-tipped blade specifically designed for non-ferrous metals (often 60 to 80 teeth). These are often called “cold-cutting” blades. Unlike abrasive wheels that grind (and create heat), these blades chip the metal away.

Best For: Cutting through a stack of panels at once. If you need to trim five panels to the same length, clamp them together and use a circular saw. It is the fastest method by far.

Safety Note: This method is loud—extremely loud. You absolutely need double ear protection (plugs and muffs). Also, wear a full face shield, as hot metal chips will be flying at high velocity.

Jigsaw with Fine Metal Blade

The jigsaw is the “Jack of all trades” for cutting metal roofing. It isn’t the fastest, but it is versatile.

Setup: Equip your jigsaw with a fine-toothed metal cutting blade (21-24 TPI or Teeth Per Inch). Make sure your jigsaw is set to a non-orbital setting (straight up and down action) to prevent the blade from snagging the thin metal.

Best For: Cutting out spaces for electrical boxes, vents, or complex curves. If you have a complicated roofline with lots of valleys and hips, your jigsaw will get a workout.

Angle Grinder with Cut-Off Wheel

This is a controversial tool in the roofing world, but it is very common.

The Controversy: An angle grinder cuts fast using friction. Friction creates heat. Heat destroys the protective zinc or Galvalume coating on the steel, leading to premature rust on the cut edge. It also throws a shower of hot sparks that can burn the paint on the panels behind you.

Best For: Heavy-gauge trim or flashing where shears struggle. It is also good for demolition if you are removing an old metal roof.

Keyword Tip: If you use an angle grinder to cut metal roofing edges, you must paint the cut edge with a primer immediately to prevent rust.

Plasma Cutter (for Advanced DIY)

If you have access to one or want to rent one, a plasma cutter is the ultimate luxury tool for this job.

How It Works: It uses compressed air and electricity to cut through conductive metals instantly.

Best For: Any cut you can imagine. It cuts like a hot knife through butter with zero physical pressure on the panel, meaning no warping whatsoever.

Why Not Use It? It requires an air compressor and electricity, which can be a pain to set up on a roof. It is also expensive. This is overkill for a shed, but great for a massive custom home project.

Tools Comparison Table

Here is a quick reference to help you decide which tool fits your budget and project:

Tool Best Used For Approximate Cost Safety Rating (1-5)

Electric Shears Long, clean straight cuts $50 – $150 4 (High Safety)

Tin Snips Detail work, trimming $15 – $30 5 (Safest)

Drill Nibbler Curves, vent holes $30 – $60 4

Circular Saw Cutting multiple panels at once Owned + $40 Blade 2 (Loud, chips fly)

Jigsaw Complicated shapes Owned + $10 Blades 3

Angle Grinder Thick trim, demo work Owned + $5 Wheel 1 (Sparks/Heat)

Plasma Cutter Precision, zero warping $300+ or Rental 2 (Fire risk)

Essential Safety Gear and Prep Before You Cut

You are dealing with metal. We cannot stress this enough: Safety first when learning how to cut metal roofing. The edges of cut metal are razor-sharp and can slice through skin with zero resistance.

The “Must-Have” PPE List

Before you even touch a tool, suit up:

- Heavy-Duty Gloves: Do not use thin gardening gloves. Get leather or cut-resistant Kevlar gloves.

- Eye Protection: Safety goggles are good; a full face shield is better, especially if using power saws.

- Hearing Protection: Cutting metal resonates. It screams. Protect your ears to prevent permanent damage.

- Long Sleeves and Pants: Flying metal chips are hot and sharp. Do not cut metal in shorts and a t-shirt.

- Respirator: If you are cutting painted metal or using an abrasive blade, you don’t want to inhale the dust.

Workspace Setup

A stable workspace is half the battle.

- Stable Surface: Use two sturdy sawhorses with 2x4s running between them to support the full length of the panel. If the panel sags while you cut, the blade will bind and kick back.

- Clamps: Never try to hold the metal with one hand and cut with the other. Use “C-clamps” or locking pliers to secure the metal to your workbench.

- Measuring Tools: Have a tape measure, a speed square, and a long straightedge (a straight piece of lumber works well) ready.

- Marking Tool: A standard pencil is hard to see on metal. Use a permanent marker or, even better, a soapstone pencil or chalk line.

Step-by-Step DIY Guide: How to Cut Metal Roofing

Now that you have your tools and your safety gear, let’s get into the actual process. Follow this step-by-step guide on how to cut metal roofing to ensure you get professional results on your first try.

Measure and Mark Your Cuts Accurately

Precision starts here. Take your tape measure and determine the length you need.

- Pro Tip: Remember to account for overhang at the eaves (usually 1 to 2 inches) to ensure water runs off into your gutters, not down your fascia.

Once you have the measurement, mark the panel on both edges. Use your straightedge to connect the dots. If you are cutting the “wrong” side (the underside) of the panel to avoid scratching the paint, remember to double-check your orientation! A classic mistake is marking the underside and realising you cut the angle backwards.

Secure the Metal Panel Firmly

Place your panel on your sawhorses or workbench. The area where you will be cutting should be supported, but there should be a gap for the blade to pass through so you don’t cut your table.

Use your clamps to lock the panel down. Metal vibrates intensely when cut with power tools. If the panel is vibrating, your tool will bounce, creating a jagged, ugly edge. The tighter the panel is clamped, the smoother the cut will be.

Choose and Set Up Your Tool

Select the tool based on the cut you are making (refer back to our tool section).

- If using a circular saw: install the blade backwards (if using a standard carbide blade) or install your metal-cutting blade. Set the blade depth so it barely extends past the thickness of the metal (about 1/4 inch). This reduces friction and heat.

- If using shears: Make sure the jaws are clean and oiled.

- If using a jigsaw: Ensure the base plate is smooth so it doesn’t scratch the paint. You can put masking tape over the base plate as a precaution.

Make the Initial Cut Slowly

Line up your blade with your mark.

- Power Up First: If using a circular saw or grinder, pull the trigger and let the tool reach full speed before the blade touches the metal. If you touch the metal and then pull the trigger, the tool will buck and damage the panel.

- Technique: Move forward with steady pressure. Do not force it. Let the tool do the cutting. If you hear the motor bogging down, you are pushing too hard.

- For Shears: You will lose a strip of metal. Align the “waste” side of the cutter with your scrap metal, so your “keep” side stays exactly on the line.

Follow Through for Clean Edges

Maintain a consistent speed all the way through the end of the panel. The end of the cut is where mistakes happen—often, the waste piece will drop off and tear the last tiny bit of metal.

- The Fix: Have a helper hold the waste piece as you finish the cut, so it doesn’t drop prematurely.

Deburring is Mandatory: Once the cut is done, you aren’t finished. Run a gloved finger (carefully!) along the edge. You will likely feel a “burr” or rough lip. Use a metal file or your sandpaper to smooth this edge gently. This prevents rust from forming on the rough steel and makes the panel safer to handle during installation.

Handle Curves and Notches

If you need to cut a hole for a vent pipe:

- Mark the circle clearly.

- Drill a “starter hole” inside the circle using a large drill bit (1/2 inch).

- Insert your jigsaw blade or nibbler into that hole.

- Cut slowly around the line.

- Use tin snips to clean up any jagged spots the power tool missed.

Inspect, Test-Fit, and Finish

Before you haul that panel up to the roof, look at the paint. Did you scratch it?

- Touch Up: If there are scratches, use a manufacturer-approved touch-up paint pen.

- Seal the Edge: If you used an abrasive blade (heat), you must primer the cut edge. If you used shears (cold cut), the galvanisation usually “heals” over the cut edge somewhat, but a little clear coat never hurts.

Take the panel up and test-fit it. Does it align perfectly? If so, congratulations! You just learned how to cut metal roofing like a pro.

Pro Tips and Common Mistakes to Avoid

Even with the best instructions, things can go wrong. Here are some advanced tips to keep you on the right track.

Common Mistakes

- Using the Wrong Blade: We see this all the time. Using a wood blade on a circular saw will result in a terrible noise, a dull blade, and a ruined panel.

- Ignoring the Swarf: “Swarf” is the industry term for the hot metal dust/chips created by cutting. If these chips land on your roof panels and it rains, they will rust immediately. This creates ugly orange spots that look like your roof is failing. Always wipe or blow off your panels immediately after cutting.

- Cutting on the Roof: Try to do all your cutting on the ground. Cutting on the roof increases the risk of slipping, and it dumps metal shavings directly onto your new roof.

Pro Tips for Success

- The “Flip” Trick: If you are using a circular saw, flip the panel over and cut from the backside (the unpainted side). This way, if the saw chips the paint, it will happen on the underside, where no one can see it.

- Tape the Line: If you are worried about scratching the paint with your tool’s base plate, put a strip of blue painter’s tape along your cut line. Mark on the tape and cut through it. Peel the tape off for a pristine finish.

- Watch the Temperature: Metal expands and contracts. Avoid cutting in extreme heat or cold if you want the absolute most precise measurements, though, for general roofing, this is a minor concern.

Maintenance and When to Call a Pro

You have the skills, but keep your tools in check. Metal cutting is hard on blades. If you notice your saw is struggling or burning the metal, swap the blade immediately. A dull blade is a dangerous blade.

When to Fold ‘Em: While this guide teaches you how to cut metal roofing, there are times you should call a pro.

- Complex Valleys: If your roof has multiple intersecting angles (hips and valleys) that require complex geometry, the waste factor can be high for a DIYer.

- Steep Pitch: If your roof is extremely steep (walking on it is difficult), the danger of handling sharp metal while balancing is too high.

- Thick Gauge: Most residential roofs are 29 or 26 gauge. If you are dealing with heavy commercial 22-gauge steel, standard DIY tools might not cut it (pun intended).

FAQs: Frequently Asked Questions

What is the absolute best tool for cutting metal roofing at home? For the average DIYer, electric metal shears (nibblers) are the best balance of safety, ease of use, and clean results. They don’t generate heat and are easy to control.

Can I use a regular saw for metal roofing? You can use a circular saw, but not with a regular wood blade. You must use a specialised non-ferrous metal cutting blade. Using a wood blade is dangerous and will ruin the cut.

Is it safe to cut metal roofing with power tools? Yes, but only if you wear proper Personal Protective Equipment (PPE). You need eye protection, hearing protection, and heavy leather gloves. Metal chips fly fast and are very hot.

How do I avoid sparks when cutting metal roofing? To avoid sparks, avoid abrasive blades (like those on angle grinders). Use “cold cutting” tools like tin snips, electric shears, or a circular saw with a carbide-tipped metal blade designed to chip metal rather than grind it.

What is the cost difference between DIY cutting and hiring a pro? Doing it yourself saves you labour costs, which are usually 60% of the total roof price. However, you need to factor in the cost of buying tools (approx. $100-$200). If you ruin several panels of learning, that cost gap narrows.