It is 2026, and the roofing industry has undergone a massive shift in priorities. As climate patterns become more unpredictable and storms grow more intense, property owners are no longer looking for just the cheapest option—they are looking for a fortress. Did you know that in 2026, over 40% of commercial roofs used hot-applied methods for unmatched waterproofing? That is a staggering number, but it makes perfect sense when you consider the value of protecting your assets.

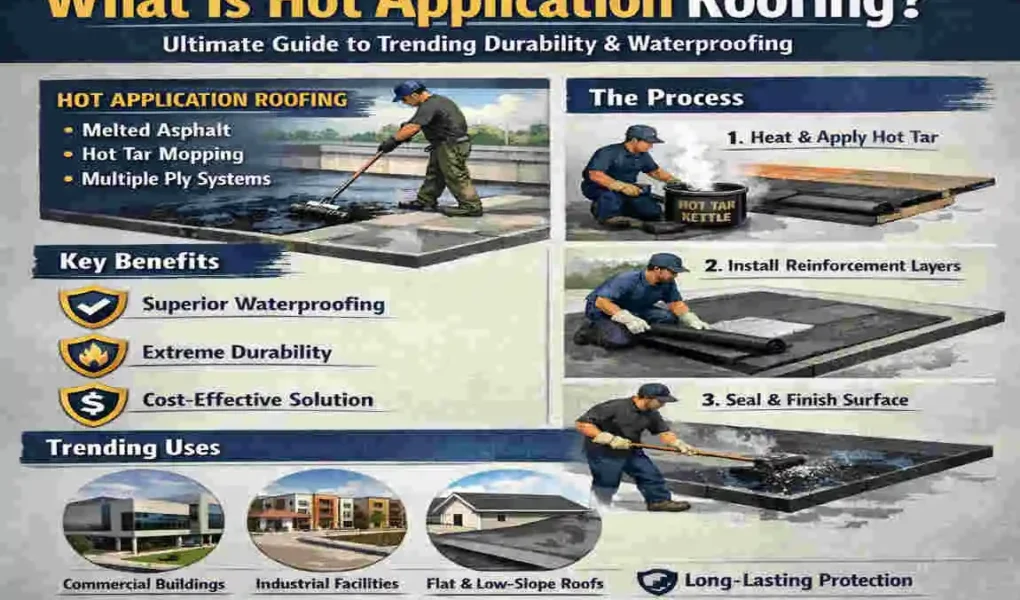

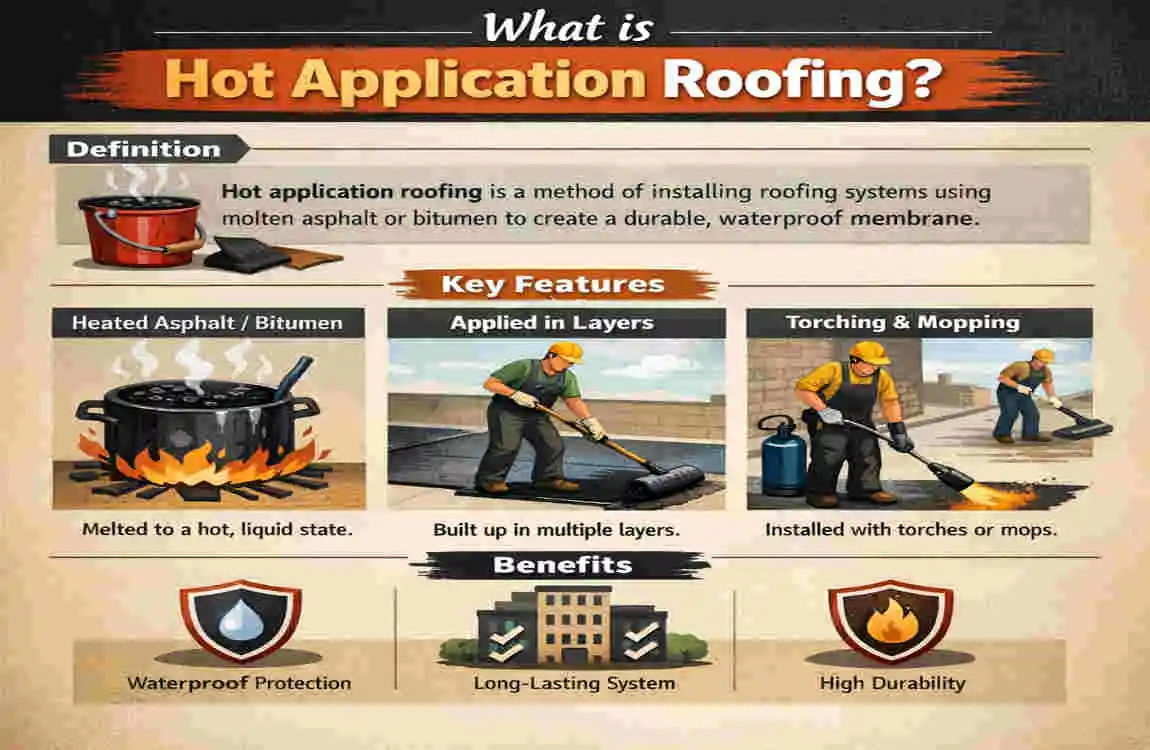

In simple terms, it is a time-tested method where materials like bitumen or asphalt are heated to a liquid state—usually between 400°F and 500°F—and applied in layers. This creates a seamless, monolithic membrane that is incredibly tough. Unlike modern “peel and stick” options, this is a heavy-duty industrial process designed for serious durability.

Definition and Basics

What Is Hot Application Roofing Exactly?

To truly understand what hot application roofing is, we need to move past the technical jargon and look at the physical process. Imagine building a lasagna, but instead of pasta and sauce, you use industrial-strength fabrics and a molten waterproofing material.

Hot application roofing creates a Built-Up Roof (BUR) or a polymer-modified bitumen system. The core of this system is the liquid asphalt (often referred to as tar or bitumen). This material is solid at room temperature. To apply it, roofing professionals place blocks of this asphalt into a large heating device called a kettle.

Inside the kettle, the material is heated until it turns into a hot, viscous liquid. This liquid is then brought up to the roof and applied—often using mops or mechanical spreaders—onto the roof deck. While the asphalt is still hot and sticky, layers of reinforcing felt (usually fiberglass or polyester) are rolled into it.

When the asphalt cools, it forms a solid, uniform, waterproof bond with the fabric. This process is repeated to build up thickness. This is fundamentally different from cold-applied roofing, which relies on solvent-based adhesives that are applied at ambient temperatures (no heat required). While cold application is safer and easier, it often lacks the instant, seamless fusion you get with the hot-melt process.

Brief History of Hot Applied Roofing

You might be thinking, “Is this a new technology?” Surprisingly, no. The concept of hot-applied roofing has been around since the mid-1800s. It is one of the oldest and most reliable roofing systems in the modern world.

It started with simple “tar and gravel” roofs. Builders in the 1880s discovered that by layering felt paper with hot pine tar or coal tar, they could create a roof that was effectively waterproof. As the oil industry boomed in the 20th century, asphalt became the standard binder because it was more stable and less brittle than coal tar.

This method reached its peak popularity during the mid-20th century. If you look at almost any factory, school, or department store built between 1950 and 1980, chances are high that it has a hot-applied BUR system.

However, in the late 1990s and early 2000s, the industry drifted toward “single-ply” systems such as TPO and EPDM because they were easier to install. But here is the twist: in the 2020s, and specifically now in 2026, we are seeing a massive resurgence in hot applications.

Why the comeback? Sustainability and resilience. Building owners realized that while single-ply roofs are cheap, they are prone to punctures and failing seams. The old-school hot-applied method, modernized with new rubberized modifiers, offers a lifespan that modern plastics struggle to match.

How Hot Application Roofing Works

Understanding the mechanics of what a hot-application roofing job requires a look at the job site. This is not a quiet process; it is an industrial operation that requires skill, timing, and strict safety protocols.

Step-by-Step Application Process

If you hire a professional crew to install a hot-applied roof, here is exactly what you can expect to see happening on your building.

Surface Preparation Before a single drop of asphalt is heated, the roof deck must be immaculate. The crew will clean the deck (concrete, steel, or wood) to remove dust, oil, and moisture. If any water is trapped beneath the asphalt, the heat from the asphalt will cause it to boil and blister, ruining the roof. A primer is often applied to help the asphalt bond to the deck.

Heating the Asphalt This is the most critical step. The solid asphalt blocks are loaded into the kettle. The temperature is monitored closely. It needs to reach the Equiviscous Temperature (EVT), the point at which the liquid is thin enough to mop but thick enough to hold the layers together. This is typically between 400°F and 500°F.

Application of the Base Ply Once the asphalt is hot, it is pumped or carried to the roof. A roofer, usually nicknamed the “mopper,” spreads a generous layer of the hot liquid onto the deck. Immediately behind him, another crew member rolls out a layer of fiberglass felt. The felt is pressed into the hot liquid, allowing the asphalt to bleed through the fabric’s pores.

Building the Plies (The BUR System) This is where the strength comes from. The process is repeated. A layer of hot asphalt, followed by a layer of felt. A typical robust system will have 3 to 5 plies (layers). This redundancy is why these roofs rarely leak—water would have to get through four or five separate waterproof barriers to reach your building.

Surfacing and UV Protection: Asphalt degrades when exposed to sunlight (UV rays). To stop this, the final coat of hot asphalt is poured, and a layer of aggregate (gravel or slag) is embedded into it while it is still hot. Alternatively, a reflective coating or a mineral-surfaced cap sheet is used.

Safety Note: This process involves open flames and extremely hot liquids. Professional crews use specialized PPE and maintain strict perimeters to ensure safety.

Tools and Materials Used

The system’s durability depends entirely on the quality of its materials. Here is a breakdown of the essential components used in hot application roofing.

The Kettle: This is a trailer-mounted tank with a propane burner underneath. It has temperature controls and an agitator to keep the asphalt mixed.

The Mops: These are not your kitchen mops. They are made of spun glass or cotton and designed to hold a massive amount of heavy, hot liquid without burning.

Bitumen Modifiers: In 2026, we rarely use plain asphalt. We use modified bitumen.

- SBS (Styrene-Butadiene-Styrene): This gives the asphalt a rubber-like quality, allowing it to stretch and flex with the building.

- APP (Atactic Polypropylene): This makes the asphalt more plastic-like and tough.

Felts: We use Type IV or Type VI fiberglass felts. These are incredibly strong fabrics that provide the roof’s tensile strength.

Table of Materials and Purposes:

MaterialPurposeKeyword Tie-In

Asphalt/Bitumen Serves as the primary waterproofing binder and glue. The core of hot application roofing.

Fiberglass Felt provides tensile strength to prevent cracking. Builds the BUR roofing system structure.

Gravel / Slag protects the asphalt from sun damage and foot traffic. Enhances trending durability features.

Base Sheet: The first layer that anchors the system to the deck. Essential for roof waterproofing.

Trending Durability Features

Why It’s Ultra-Durable (5+ Decades Lifespan)

When we talk about what is hot application roofing, the conversation always comes back to one thing: longevity. A standard single-ply roof might last you 20 years if you are lucky. A well-installed hot-applied roof? You are looking at 30 to 50 years, easily.

The secret lies in the multi-ply construction. Most roofing failures result from a puncture. Maybe a technician drops a tool, or a storm blows a tree branch onto the roof. On a single-ply roof, that puncture goes straight through to the insulation. On a 4-ply hot roof, that puncture might only damage the top layer, leaving three more waterproof layers intact underneath.

Furthermore, hot asphalt has self-healing properties. In the summer heat, the bitumen softens slightly. If there are minor micro-cracks or small abrasions, the heat allows the material to flow and fuse back together, effectively sealing the wound.

We also cannot ignore insulation. These roofs are often built as “hot roof” variants (unvented), which can achieve impressive insulation ratings, sometimes reaching R-31. This keeps the heat out during those scorching summers and holds in the warmth during the winter.

Superior Waterproofing Mechanism

For flat roofs, water is the enemy. It pools. It sits. It finds the tiniest opening.

Hot application roofing is superior because it creates a monolithic membrane. This means the roof is essentially one single piece. Because the layers are fused chemically by heat, there are no “seams” in the traditional sense.

In other systems, the sheets are glued or taped together. Over time, that glue dries out and the tape peels. In hot roofing, the bond is molecular. This makes it the ideal choice for “zero slope” or dead-level roofs where water might stand for days.

2026 Trends Boosting Popularity

Why is this method trending right now?

- Climate Adaptation: In places like Pakistan, particularly Lahore, monsoon rains are becoming heavier. Business owners need roofs that can handle “ponding water” (water that stays on the roof for 48+ hours). Hot applied systems are the best at this.

- Eco-Modifiers: In 2026, manufacturers developed “low-fume” asphalts and bio-based modifiers, reducing environmental impact and odor during installation.

- Hybrid Solar Roofs: The sturdy nature of a BUR roof makes it the perfect platform for heavy solar panel installations. Unlike flimsy membranes, a hot asphalt roof can support the weight of solar arrays without tearing.

Pros and Cons Compared to Alternatives

To make an informed decision, you need to comparehot-appliedn roofingwithe other market contenders, primarily Cold-Applied systems and Single-Ply (like TPO).

Comparison Table:

FeatureHot Application RoofingCold-Applied RoofingSingle-Ply (TPO)

Durability 30-50 Years (Best) 15-25 Years 20-30 Years

Waterproofing Excellent (Seamless) Good Fair (Reliance on seams)

Cost $5 – $8 per sq ft $4 – $6 per sq ft $6 – $10 per sq ft

Application Heat Required (Kettles) Ambient (Adhesives) Mechanical / Heat Weld

Puncture Resist High (Multi-layer) Moderate Low (Single layer)

The Pros

- Redundancy: As mentioned, having multiple layers is a safety net that other roofs do not provide.

- Fire Resistance: The gravel topping provides excellent fire ratings, a crucial feature for commercial buildings in dense urban areas.

- Proven Track Record: This is not experimental. We know exactly how these roofs perform over 50 years because they have been doing it for a century.

The Cons

- The Smell: There is no getting around it—hot asphalt has a distinct, strong odor. While it is temporary, it can be a nuisance for building occupants during installation.

- Safety Risks: Working with 500°F liquid carries burn risks. It requires a highly skilled, professional crew, not a general handyman.

- Weight: A 4-ply roof with gravel is heavy. You need to ensure your building structure can support the load.

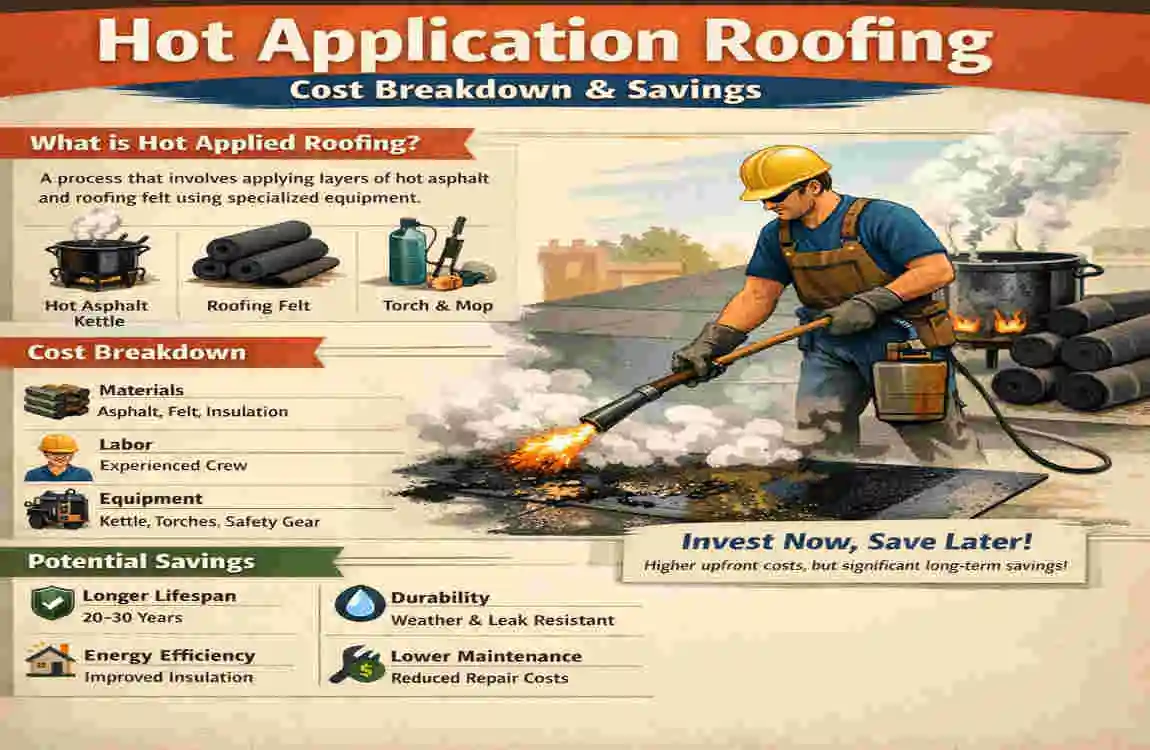

Cost Breakdown and Savings

Average Costs in 2026 (US/PK Context)

One of the biggest misconceptions about hot-applied roofing is that it is prohibitively expensive. While the labor is intensive, the materials (asphalt and felt) are relatively affordable compared to high-tech synthetics.

In the US market in 2026, you can expect to pay between $5.00 and $10.00 per square foot for a fully installed system. The variance depends on the number of layers (plies) and the difficulty of access to the roof.

In Pakistan (e.g., Lahore or Punjab), labor costs are lower, but imported bitumen prices fluctuate. Generally, labor might cost around PKR 800 to PKR 1200 per square meter, with material costs added on top.

Factors that influence your price:

- Roof Size: Larger roofs generally cost less per square foot due to economies of scale.

- Layers: A 3-ply roof is cheaper than a 5-ply roof, but less durable.

- Gravel vs. Cap Sheet: Gravel is cheaper but heavier. Granulated cap sheets look nicer but cost more.

Long-Term Savings

Do not just look at the sticker price. You have to look at the Lifecycle Cost.

If you install a TPO roof for $6/sq ft and it lasts 20 years, your annual cost is $0.30. If you install a Hot Applied roof for $7/sq ft and it lasts 40 years, your cost is $0.17 per year.

That is nearly 50% savings over the life of the building.

Additionally, modern hot roofs with reflective coatings fall into the “cool roof” category. This can lower your air conditioning bills by reflecting sunlight rather than absorbing it. In a hot climate, this energy efficiency pays for the roof over time.

Installation Tips for Business Owners

If you have decided that hot-applied roofing is the right choice for your property, you need to manage the project effectively. This is not a DIY job.

Hire Certified Professionals. Ensure your contractor is certified by major manufacturers (like GAF, Soprema, or local equivalents). Handling a kettle requires specific licenses and insurance. Ask for proof of “Hot Work” safety training.

Check the Weather Hot asphalt hates moisture. Do not schedule this installation during the rainy season or on days with high humidity. The deck must be bone dry.

Manage the Odor. If you are roofing an occupied building (such as an office or apartment), ask the contractor to use low-VOC additives or a fume recovery system. You should also close the roof air intake vents to prevent the smell from being sucked into the AC system.

Maintenance plan Even though these roofs are tough, they need love.

- Annual Inspections: Check for loose flashing.

- Gravel Refresh: Over time, wind can blow the gravel away, exposing the asphalt. You may need to sweep it back in place or add more every 5-10 years.

- Drain Cleaning: Keep your scuppers and drains clear. Standing water is okay for the roof, but bad for the building’s weight load.

Common Myths Debunked

There is a lot of misinformation out there about what hot application roofing is. Let’s clear up a few myths.

“Hot roofing is too dangerous and illegal.”Fact: It is not illegal. It is highly regulated. With modern kettles that have automatic shut-offs and temperature guards, the risk is managed effectively. It remains the standard for high-value commercial projects.

“It makes the building too hot.”Fact: This was true for black tar roofs. However, modern systems use white gravel or reflective aluminum coatings as a top layer. This reflects UV rays, keeping the building just as cool as a white TPO roof.

“It is outdated technology.”Fact: Is a brick house outdated? Is a leather boot outdated? Some things are classics for a reason. With the addition of SBS polymers (rubberizing the asphalt), this “old” tech is actually more chemically resistant than many new plastics.

FAQ Section

Here are some quick answers to the most pressing questions about hot-applied roofing.

What Is Hot Application Roofing Used For?

It is primarily used for flat or low-slope commercial roofs. You will see it in schools, hospitals, factories, and warehouses. It is also used for waterproofing foundation walls and plaza decks (roofs you can walk on).

How Long Does Hot Application Roofing Last?

If installed correctly with 4 or 5 plies, a hot-applied roof can last 30 to 50 years. With proper maintenance, some have been known to last even longer.

Is Hot Applied Roofing Eco-Friendly?

Surprisingly, yes. Asphalt is a byproduct of the oil industry that would otherwise be waste. Furthermore, at the end of the roof’s life, the asphalt can often be recycled for road paving. The longevity also means fewer roofs end up in landfills than with single-ply membranes, which are replaced more often.

Can I Walk on a Hot Applied Roof?

Yes. These roofs are very tough. Unlike single-ply membranes, which can puncture if you step on a sharp rock, a gravel-surfaced BUR roof can withstand heavy foot traffic during HVAC maintenance.

Does it Smell Bad Forever?

No. The smell is only present during the application while the asphalt is liquid. Once it cools and solidifies (usually within 24 hours), the smell disappears completely.