Hey there, reader! If you’re dreaming about building your own house or just curious about the nuts and bolts of house construction, you’ve landed in the right spot. Lumber is the backbone of most houses, forming everything from sturdy frames to cozy interiors. But here’s the big question that pops up for many: how much lumber is needed to build a house? It’s not a one-size-fits-all answer, and that’s what makes it fascinating.

Understanding Lumber in House Construction

Lumber isn’t just any old wood—it’s the essential material that holds a house together. Think of it as the skeleton of your house. But not all lumber is created equal. Let’s unpack the types and roles it plays, so you can see why figuring out how much lumber is needed to build a house starts with knowing your options.

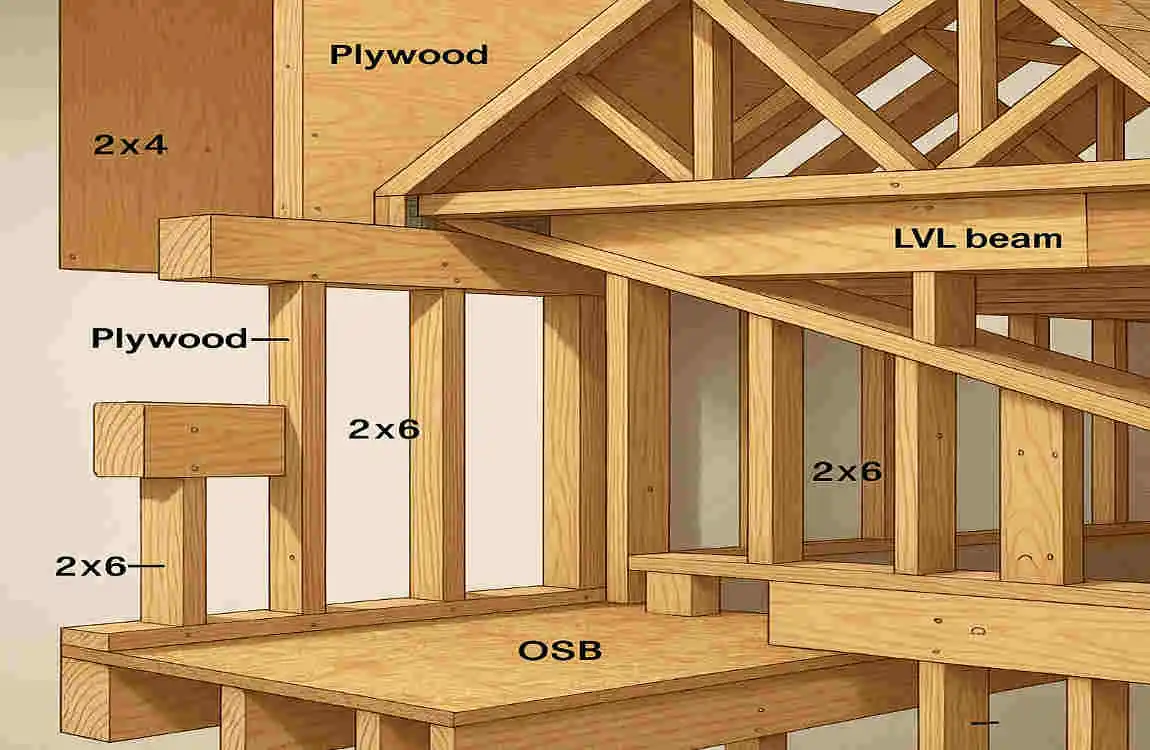

Types of Lumber Commonly Used

First off, softwood comes from trees like pine, spruce, and fir. It’s popular because it’s affordable and easy to work with. Builders love it for framing walls and roofs since it grows quickly and is readily available.

On the flip side, hardwood from oaks or maples is more rigid and more durable. You might see it in floors or furniture inside the house, but it’s pricier and less common for basic structures.

Then there’s engineered wood, like plywood or oriented strand board (OSB). These are artificial from wood fibers and glue, offering strength without wasting natural resources. They’re excellent for sheathing or subfloors.

Imagine you’re picking ingredients for a recipe—each type of lumber serves a purpose, and choosing the right one affects the total amount you’ll need.

Role of Lumber in Different House Parts

Lumber shows up everywhere in a house. In the foundation, treated lumber might support concrete forms or create basements. It’s all about providing a stable base.

For framing, that’s where the bulk of lumber goes. Walls, floors, and ceilings get built with studs, joists, and rafters. This is the framework that gives your house its shape.

Don’t forget roofing—trusses and beams made from lumber keep the roof from caving in. And inside, lumber forms doors, windows, and even cabinetry.

Reader, picture walking through your future house. Every step on the floor, every wall you lean on—lumber makes it possible. That’s why estimating how much lumber is needed to build a house depends on these components.

Sustainability and Lumber Sourcing

We can’t ignore the environment. Sustainable lumber comes from forests managed responsibly, reducing deforestation. Certifications like FSC (Forest Stewardship Council) ensure you’re not harming the planet.

Sourcing locally cuts down on transport emissions and supports your community. Plus, it might lower costs. As you plan, ask yourself: How can I make my build eco-friendly? It could influence the types and amounts of lumber you choose.

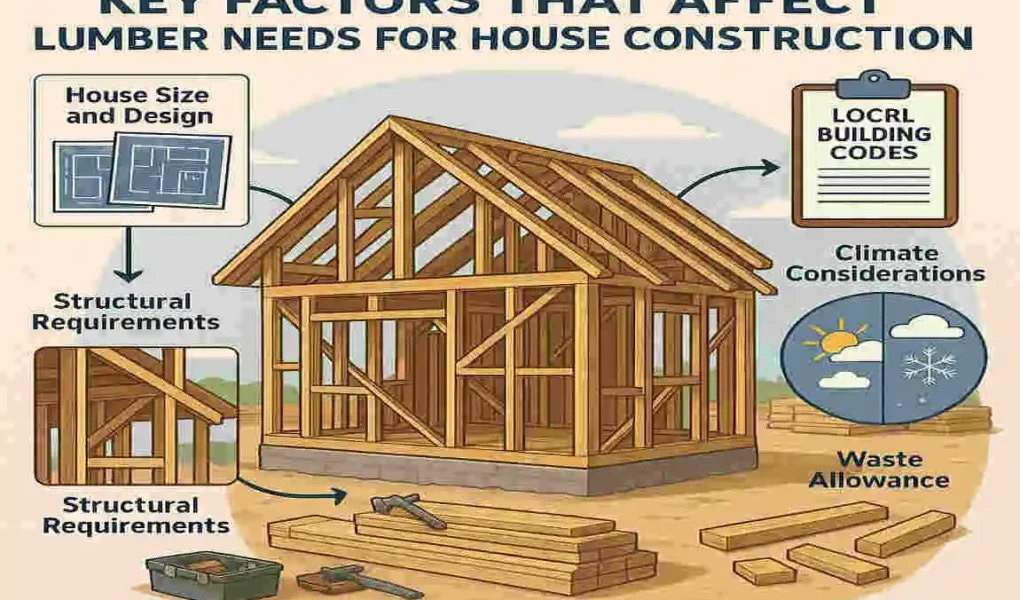

Key Factors Affecting How Much Lumber Is Needed to Build a House

Now, let’s get to the heart of it. Several factors contribute to determining the amount of lumber needed to build a house. We’ll explore each one, so you can see how they add up. Think of this as your roadmap to more thoughtful planning.

You may also read (building a home steps to take in todays market).

House Size and Design

Size matters—a lot. The total square footage directly impacts lumber needs. A bigger house means more walls, floors, and roofs, which all require more wood.

For example, a 2,000-square-foot house might need around 10,000 to 15,000 board feet of lumber for framing alone. That’s a rough estimate, but it shows how scaling up increases the tally.

House style plays a role, too. A simple ranch-style house with one level uses less lumber than a multi-story colonial with intricate details like gables or dormers.

Contemporary designs with open floor plans might save on interior walls, reducing lumber. But add complexity like vaulted ceilings, and you’re looking at extra beams and supports.

Consider the number of floors. A two-story house needs stronger framing for the upper level, bumping up the lumber count. Ceiling height also factors in—taller rooms mean longer studs.

Reader, what’s your vision? A cozy bungalow or a sprawling estate? Your choices here will shape how much lumber is needed to build a house.

Architectural Plans and Blueprints

Blueprints are like the instruction manual for your build. Detailed plans help estimate lumber precisely, avoiding guesswork.

Framing design dictates everything. Thicker walls for better insulation require wider lumber, increasing the total volume.

Custom designs often demand more unique cuts and pieces compared to standard cookie-cutter plans, which are optimized for efficiency.

Consider this: A blueprint with open spaces reduces the need for partition walls, saving lumber. But if you’re adding a home theater or extra bathrooms, expect the needs to rise.

Always consult an architect early. They can tweak designs to minimize waste while ensuring your home is safe and beautiful.

Building Code Requirements and Regulations

Local rules aren’t just red tape—they ensure your house stands the test of time. Codes specify minimum lumber sizes for safety, like thicker beams in earthquake-prone areas.

Structural standards require reinforced framing, adding to the lumber pile. In high-wind zones, you could need hurricane ties or extra bracing.

Fire safety often means using treated or fire-resistant lumber, which may not change the quantity but affects the type and cost.

Insulation rules could influence wall thickness, indirectly boosting lumber use. Check your local codes, reader—they vary by state or even city.

Ignoring them? That’s a recipe for delays and extra expenses. Better to factor them in when calculating how much lumber is needed to build a house.

Structural Components of the House

Let’s break down the significant parts. The foundation might use lumber for forms or sills, though concrete often takes the lead.

Framing is the lumber hog—studs every 16 inches, joists for floors, rafters for roofs. Closer spacing means more pieces.

Roofing systems with complex trusses can demand specialized lumber, while simple gable roofs are more straightforward.

Flooring may involve subfloors made of plywood, and interior partitions typically include studs for rooms.

Even cabinetry and built-ins chip in. Joist spacing and beam sizes? Wider spacing saves lumber but requires stronger pieces.

Reader, visualize your layout. More rooms equal more walls, which equals more lumber. It’s all connected.

Lumber Grade and Quality

Lumber gets graded based on strength and appearance. Select grades are top-notch, with fewer knots, ideal for visible areas.

Lower grades like #2 are fine for hidden framing but might need more pieces if they’re weaker.

Higher-grade lumber can reduce overall quantity because it’s stronger—you might space studs farther apart or use fewer supports.

Durability matters too. Treated lumber resists rot, lasting longer in damp areas, potentially saving on replacements later.

Choose wisely, and you could trim your total needs. Ask suppliers about grades to match your project’s demands.

Climate and Environmental Considerations

Weather isn’t just small talk—it shapes your lumber choices. In humid areas, you need rot-resistant wood, like pressure-treated options.

Cold climates may require insulated framing, which involves adding layers that increase lumber volume.

Hot, dry spots? Fire-resistant lumber could be mandatory, affecting types but not always quantity.

Environmental factors, such as pests, necessitate the use of treated wood to prevent termite damage. Coastal builds often require salt-resistant materials.

Think local, reader. Your climate could add 10-20% more lumber for treatments or reinforcements when figuring out how much lumber is needed to build a house.

Construction Techniques

How you build changes everything. Traditional stick framing is built on-site, piece by piece, which can lead to more waste.

Modular construction prefabricates sections in a factory, optimizing lumber use and reducing scraps.

Panelized methods use pre-cut panels, slashing on-site cutting and thus waste.

Prefabrication boosts efficiency—think less overage. It’s like assembling a puzzle with perfect pieces.

If you’re going green, techniques like advanced framing minimize lumber by optimizing layouts to reduce waste. Which method suits you?

Estimating Lumber Needs: Practical Approaches

Okay, you’ve got the factors—now how do you crunch the numbers for how much lumber is needed to build a house? Let’s make it practical.

A basic rule of thumb: For a standard single-family home, expect about 6-8 board feet per square foot of floor area. So, a 2,500 sq ft house needs 15,000-20,000 board feet.

But that’s rough. Software like Home Designer or online calculators from sites like Builders Calculator refine this based on your plans.

Consult pros—an architect or builder can provide a detailed takeoff, listing every piece.

Here’s a simple table to illustrate estimates for different house sizes:

House Size (Sq Ft)Estimated Lumber (Board Feet)Notes

1,000 6,000-8,000 Basic single-story

2,000 12,000-16,000 Two-story with extras

3,000 18,000-24,000 Complex design, multi-level

4,000+ 24,000+ Custom features, large scale

Remember, these are ballparks. Input your specifics for accuracy.

Cost Implications of Lumber Quantity

Lumber isn’t cheap, and it hits your wall directly. More wood means higher bills, especially with market prices fluctuating.

Current averages? Framing lumber might run $500-$1,000 per 1,000 board feet, depending on type and location.

Seasonal spikes—think summer building booms—can jack up costs. Global events, such as supply chain issues, also play a role.

To optimize, buy in bulk or during off-seasons. Reduce waste through precise planning, saving 5-10% on materials.

Reader, budget smartly. Understanding how much lumber is needed to build a house helps forecast expenses accurately.

Tips for Managing Lumber Needs Efficiently

Want to avoid headaches? Here are some practical tips.

First, plan—order 10-15% extra to cover cuts and mistakes, but not so much that you waste money.

Measure twice, cut once. Accurate blueprints prevent shortages.

For sustainability, source from certified suppliers and recycle scraps.

Here’s a quick list of waste-reduction strategies:

- Use advanced framing techniques to space studs efficiently.

- Opt for prefabricated components to minimize on-site errors.

- Track inventory daily during construction.

- Donate unused lumber to community projects.

Engage with suppliers early—they can advise on bulk deals and alternatives.

By managing your project well, you’ll keep it on track and eco-friendly.

You may also read (step by step guide to building an edgeland house).