Imagine walking into your home on a chilly morning. Instead of stepping onto a hard, unforgiving, and freezing concrete slab, your feet land on the warm, organic texture of real wood. It changes the entire vibe of a room, doesn’t it? It turns a basement or a living area from a cold industrial space into a cozy sanctuary.

Many homeowners look at their concrete slabs and feel stuck. They assume that getting hardwood floors installed is strictly a job for expensive professionals, or they worry that wood and concrete don’t mix. But here is the good news: learning how to install glue-down wood flooring on concrete is entirely within your reach. In fact, it is one of the most rewarding DIY projects you can tackle.

By choosing the glue-down method, you aren’t just saving a significant amount of money—usually between $3 to $5 per square foot in labor costs—you are also creating a permanent, solid floor that feels incredible underfoot. Unlike floating floors, which can sometimes sound hollow or feel bouncy, a glued floor feels solid as a rock because it is bonded directly to the foundation.

Tools and Materials: Essential List for Success

You wouldn’t bake a cake without checking if you have flour and eggs first, right? Installing a floor is no different. Having the right tools on hand before you pop the lid off that adhesive bucket is crucial. Once the glue starts to cure, you won’t have time to run to the hardware store.

Here is a detailed checklist of what you need to gather.

The Essential Tools

To do the job right, you need tools that are specific to flooring. Don’t try to improvise here; using the wrong trowel, for instance, can lead to a failed installation.

- Notched Trowel: This is your most important tool. You will likely need a square-notch trowel (often 1/4″ x 1/4″ or 1/4″ x 3/16″), but always check the adhesive bucket for the manufacturer’s recommendation. The notch size determines exactly how much glue hits the floor.

- 100-lb Floor Roller: You usually rent this. It presses the wood firmly into the adhesive to ensure a proper bond.

- Tapping Block and Pull Bar: These help you snug the planks together without damaging the tongue or groove.

- Rubber Mallet: For striking the tapping block.

- Tape Measure and Chalk Line: For keeping your rows straight.

- Utility Knife: For opening boxes and cutting easier materials.

- Jigsaw or Circular Saw: You will need this for cutting the wood planks to size.

- Knee Pads: Trust me on this one. Your knees will thank you later.

- Moisture Meter: To test the concrete slab before you begin.

- Spacers: To maintain the gap between the floor and the wall.

The Materials

- Engineered Wood Flooring: Acclimated to your room’s temperature for 7 to 14 days.

- Urethane Wood Flooring Adhesive: This is the “glue” in glue-down.

- Concrete Primer/Sealer: If your moisture tests show high humidity.

- Blue painters’ tape: To hold rows together while the glue dries (if necessary).

- Adhesive Remover Towels: To clean up wet glue immediately.

Pro Tip Table: Why These Items Matter

It helps to know why you are buying these specific items. Here is a quick breakdown to help you shop smarter.

Item: Why It’s Essential, Recommended Type/Brand Ideas

Urethane Adhesive. It stays flexible after drying, allowing wood to expand/contract without popping off the concrete. Bostik’s BEST or Roberts 1407 (~$50+/gallon)

Notched Trowel Ensures an even “spread rate.” Too much glue is messy; too little causes loose boards. Goldblatt or QEP (Match notch to glue specs)

Moisture Meter Concrete looks dry even when it’s wet. This prevents your floor from warping later. Wagner or General Tools

Adhesive Remover: Urethane glue is incredibly strong. Water will not clean it off your finished floor. Bostik’s Ultimate or Mineral Spirits

Budgeting Note: When planning your budget, expect materials (adhesive, moisture barriers, and sundries) to cost between $2 and $4 per square foot, on top of the cost of your wood. It sounds steep, but quality adhesive is the life insurance policy for your floor.

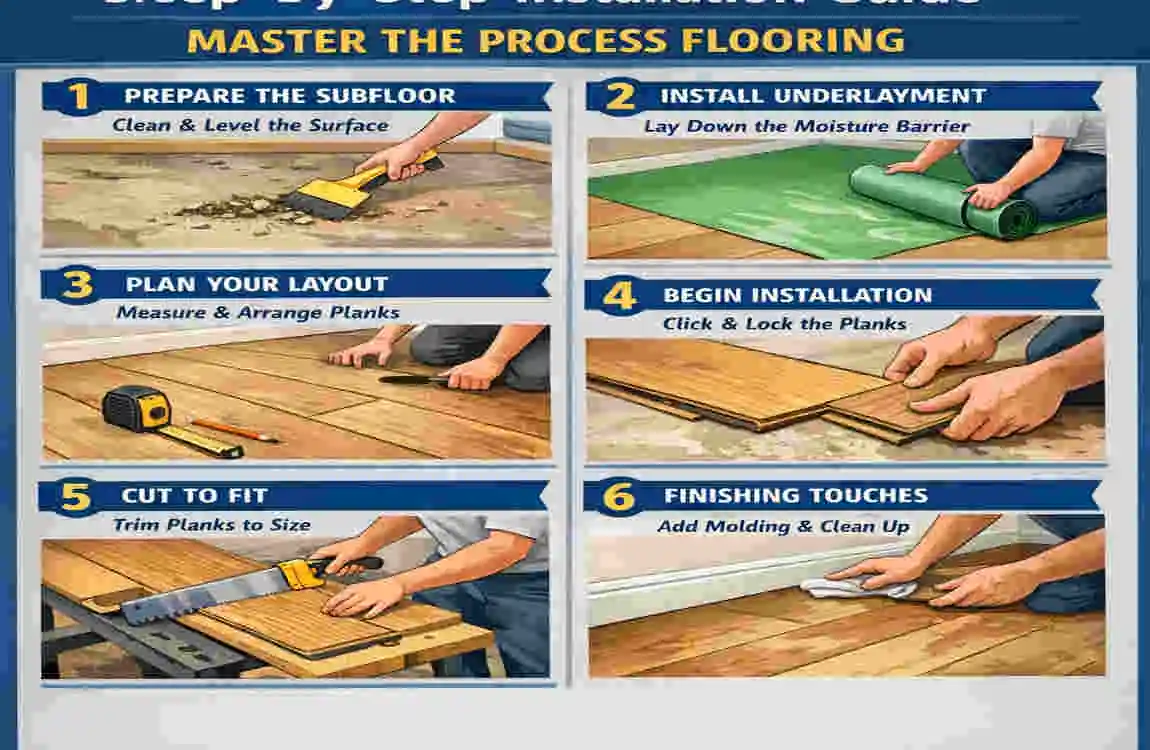

Preparation Steps: Prepping Your Concrete Slab Like a Pro

If you take one thing away from this article, let it be this: The success of your glue-down wood flooring on concrete depends entirely on the subfloor. You cannot glue wood to a dirty, wet, or uneven slab and expect it to stay there.

Think of the concrete as the foundation of a house. If it is shaky, everything built on top of it will eventually fail. Here is how to prep like a professional installer.

Assess the Levelness

Your concrete needs to be flat. Not necessarily “level” (like a countertop), but “flat” (no hills or valleys).

- Take a straight edge (a 6-foot level or a straight board) and lay it on the floor.

- Look for gaps under the board. The industry standard usually requires a variance of no more than 3/16 of an inch over a 10-foot radius.

- The Fix: If you have low spots (valleys), fill them with a cement-based patching compound or a self-leveling underlayment. If you have high spots (hills), you may need to grind them down with a concrete grinder.

The Critical Moisture Test

Concrete is like a hard sponge. It absorbs moisture from the ground and releases it into the air. If you glue wood over damp concrete, the wood will absorb that moisture, swell, and cup (where the edges raise up).

- The Pin Test: Use a concrete moisture meter. Generally, you want the moisture content to be below 3 to 4 lbs per 1,000 sq. ft. per 24 hours (calcium chloride test) or under 75-80% relative humidity inside the slab.

- The DIY “Plastic Sheet” Test: If you don’t have a meter, tape a 2×2-foot square of clear plastic sheeting to the floor with duct tape. Wait 48 hours. If the concrete is dark or there are water droplets under the plastic, your slab is too wet.

- The Fix: If moisture is present, you must apply a moisture barrier primer or use a 2-in-1 adhesive that includes a moisture vapor retarder.

Cleanliness is Key

Adhesive bonds to the top layer of the floor. If that top layer is dust, paint, or oil, the glue sticks to the dust, not the concrete.

- Scrape off old paint, drywall mud, or grease.

- Sweep thoroughly.

- Vacuum the entire floor. Then, vacuum it again.

- Pro Tip: Wipe the floor with a damp (not soaking) cloth to pick up fine dust just before starting the installation layout.

Acclimate Your Wood

While you are prepping the slab, your wood should be sitting in the room where it will be installed.

- Stack the boxes in the room. Open the ends of the boxes to let air circulate.

- Let them sit for 7 to 14 days.

- Maintain the room temperature between 60°F and 80°F. This prevents the wood from shocking (shrinking or expanding rapidly) once glued down.

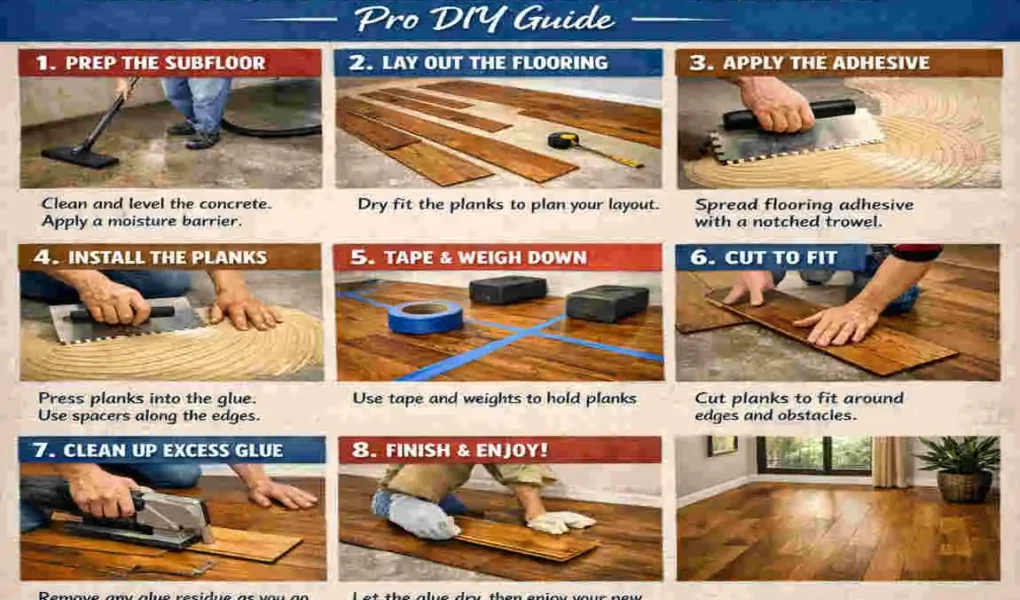

Step-by-Step Installation Guide: Master the Process

Now that your slab is clean, flat, and dry, and your wood is acclimated, it is time for the fun part. This is where your vision comes to life. We will break this down into manageable phases, so you don’t feel overwhelmed.

Dry-Fit Layout for a Perfect Fit

Never start gluing against a wall without a plan. Walls are rarely perfectly straight, and you don’t want to end up with a tiny, awkward sliver of wood at the other side of the room.

- Find Your Starting Line: Measure the width of the room. Snap a chalk line parallel to your longest wall. Usually, you want to start near the main exterior wall.

- Calculate the Last Row: Divide the room width by the width of your planks. If the remainder is less than 2 inches, trim your first row so that both the first and last rows are a decent width.

- Rack the Board: Open 3 or 4 boxes of wood at once. Wood is a natural product, and color varies. Mixing planks from different boxes ensures you don’t have a patch of dark wood next to a patch of light wood.

- Dry Lay: Lay out the first few rows without glue. This helps you visualize the stagger. You want the short ends of the boards to be at least 6 inches apart from the short ends in the previous row (often called the “stagger”).

Spreading Adhesive and Laying the First Row

This is the “point of no return.” Once the glue is down, the clock starts ticking.

- Pour and Spread: Pour a small amount of adhesive onto the concrete near your starting chalk line. Hold your notched trowel at a 45-degree angle. Press down firmly so the teeth of the trowel scrape against the concrete. You should leave behind ridges of glue, not a solid pool.

- Work in Sections: Do not spread glue over the whole room! Spread a section about 2 to 3 feet wide (about the width of two or three rows of flooring) along your starting line.

- The Starting Rows: Place your first board carefully. Ensure the tongue (or groove, depending on manufacturer instructions) is facing the wall.

- Expansion Gaps: Place spacers between the board and the wall. You need a 1/2-inch to 3/4-inch gap. This is non-negotiable. Wood expands, and if it hits the wall, it will buckle.

- Check the Line: Ensure this first row is perfectly straight along your chalk line. If this row is crooked, the whole room will be crooked.

Installing Middle and Final Rows

Once you have the first few rows set, you can get into a rhythm. This is where you will see rapid progress.

- The “H” Pattern: Keep staggering your seams. Avoid “stair-stepping” patterns that look artificial. Random is better.

- Tap it Tight: As you lay each plank into the wet adhesive, use your tapping block and mallet to snug it against the previous row. You want a tight fit, but don’t hammer so hard that you buckle the floor.

- Wipe as You Go: If any glue squeezes up between the boards, wipe it immediately with your adhesive remover towel. Urethane glue is a nightmare to remove once dried.

- Roll the Floor: Every time you finish a section (about 100 sq ft), use the 100-lb floor roller. Roll back and forth. This squishes the ridges of glue down, ensuring the wood has 100% contact with the concrete. This is the secret to a solid-feeling floor.

- Cutting Planks: When you reach the end of a row, measure the distance to the wall (minus the expansion gap). Cut the plank with your saw. Use the leftover piece to start the next row (if it’s long enough).

Phase 4: Finishing Edges and Trim

You are in the home stretch! The hard labor is done, and now it is time to make it look pretty.

- Let it cure: Do not walk on the floor immediately. Check the glue bucket for “cure times.” Usually, light foot traffic is okay after 12-16 hours, but heavy furniture should wait 24-48 hours.

- Remove Spacers: Pull out all the plastic spacers around the perimeter.

- Install Trim: You will have a gap between the floor and the wall. Cover this with baseboards or quarter-round molding.

- Important: Nail the trim into the wall, not into the floor. The floor needs to be able to slide under the trim as it expands and contracts.

- Transitions: install T-moldings or reducers where the wood meets tile, carpet, or other floorings.

Common Mistakes and Pro Troubleshooting

Even the handiest DIYers can run into hiccups. Here are the most common pitfalls when learning how to install glue-down wood flooring on concrete and how to solve them.

“There is glue everywhere!”

- The Problem: You used too much glue or were messy with the trowel.

- The Fix: Stop. Clean your hands. Clean the tools. Use the adhesive remover wipes instantly. If glue cures on the surface of the wood, it can ruin the finish.

“The boards aren’t sticking.”

- The Problem: You waited too long. Adhesive has a “flash time” or “open time.” If you spread glue and wait 60 minutes, it might skin over and lose its stickiness.

- The Fix: Scrape up the dried glue and apply fresh adhesive. Only spread as much as you can cover in 30 to 45 minutes.

“The floor sounds hollow in one spot.”

- The Problem: The concrete wasn’t flat, or you didn’t use the heavy roller.

- The Fix: If it is a small spot, you can buy a wood floor repair kit. This involves drilling a tiny hole and injecting liquid adhesive with a syringe to fill the void.

“My rows are bowing.”

- The Problem: You are pushing too hard with the tapping block, or the first row slipped.

- The Fix: Use blue painter’s tape to strap the rows together as they dry. This holds them tight and keeps them straight while the glue sets.

Maintenance and Long-Term Care

Congratulations! You have successfully installed your floor. Now, you want to keep it looking brand new for the next 30 years. Glue-down floors on concrete are incredibly durable, but they need specific care.

- No Wet Mops: Never pour water on your wood floor. Water causes swelling. Use a damp microfiber mop with a cleaner specifically designed for hardwood flooring.

- Skip the Steam: Steam mops force high-heat moisture into the grain. This is a quick way to ruin the finish and the glue bond. Avoid them entirely.

- Humidity Control: Wood breathes. In the winter, your home gets dry, and wood shrinks (creating gaps). In summer, it gets humid, and wood expands. Try to keep your home’s humidity between 35% and 55% to minimize this movement.

- Furniture Pads: Put felt pads under every chair leg, sofa, and table. Concrete is hard, so if you drag a heavy chair, the wood is being pinched between the leg and the concrete, which scratches easily.

FAQs: Quick Answers to Top Questions

Can I install solid hardwood on concrete? Technically, yes, but it is risky. Solid wood expands and contracts much more than engineered wood. For concrete slabs, especially in basements, engineered hardwood is the superior choice because it is dimensionally stable and less likely to warp.

How long does the glue take to dry? Most urethane adhesives allow for light foot traffic after 12 to 16 hours. However, for a full cure (moving heavy furniture back in), it is best to wait 24 to 48 hours. Always check the bucket label for your specific brand.

Is this method suitable for a basement? Yes! Glue-down is excellent for basements if the moisture is controlled. Because basements are below grade, moisture pressure is higher. You absolutely must use a high-quality moisture barrier adhesive or apply a separate sealer before gluing.

What is the best adhesive for glue-down wood flooring on concrete? Urethane-based adhesives are the gold standard. Brands like Bostik, Roberts, and Titebond make excellent versions. Look for “polymer” or “urethane” on the label. Avoid water-based glues for engineered wood on concrete, as the water in the glue can swell the wood.

How much does it cost to do this myself? If you DIY, you are paying for materials only. Expect to pay between $4 and $8 per square foot total. This includes the wood (usually $3-$6/sq ft) and the adhesive/trowels/sundries ($1-$2/sq ft). A professional install would add another $3 to $5 per square foot on top of that.

Can I glue over old vinyl or tile? Sometimes, but it is risky. The adhesive is designed to bond to porous concrete. Vinyl or glazed tile is non-porous. It is almost always better to remove the old flooring and grind the concrete clean to ensure a permanent bond.