You notice a few shingles missing on your roof after a heavy storm, or perhaps your roof is simply aging and looking a bit worn. You decide it is finally time to bite the bullet and call a local contractor for an estimate. You are prepared for the big numbers, but then the contractor looks at you and says, “Well, it looks like you’re going to need about 25 squares to get this job done.”

You pause. 25 squares? You look up at your roof, and it certainly looks like a lot more than twenty-five individual tiles. Did he mean 25 shingles? Or is he talking about a specific shape? Suddenly, you feel a bit lost in the jargon, and you worry that this confusion might lead to you overpaying for materials you don’t understand.

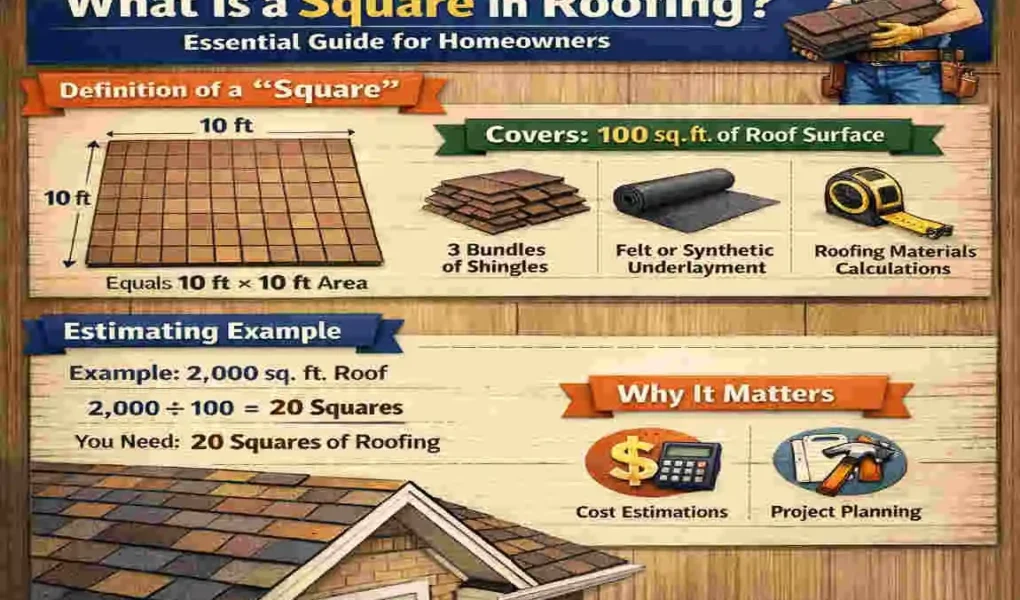

In short, a roofing square is a standard unit of measurement equal to 100 square feet of roof area. It is the gold standard for pricing, ordering, and installing materials. Understanding this single concept can save you from miscalculating your budget by thousands of dollars.

Roofing Square Basics

To really grasp the concept, we need to strip away the technical complexity and look at the core definition. As we mentioned, one roofing square equals 100 square feet.

This doesn’t necessarily mean a perfect $10 \times 10$ foot square, although that is the easiest way to visualize it. A roofing square is a unit of measure for the total surface area of a roof. Whether that area is spread out in a long, thin strip that is 5 feet wide and 20 feet long, or a perfect block, if it equals 100 square feet, it is “one square.”

Historical Origin: Why Not Just Use Square Feet?

You might be wondering why roofers complicate things with a new unit of measurement when “square feet” works just fine for flooring and painting. The origin of the “square” goes back to the history of shingle manufacturing.

Decades ago, manufacturers and suppliers needed a shorthand way to sell materials in bulk. Selling individual shingles was impossible, and selling by the square foot resulted in massive, unwieldy numbers. The industry adopted the “square” as a way to bundle materials efficiently. It became the shorthand for efficiency on the job site. It is much easier for a foreman to shout, “Bring up three squares!” than to say, “Bring up enough shingles to cover 300 square feet!”

A Visual Example for Clarity

Let’s visualize this to make it stick.

Imagine you take a tape measure and mark out a box on your driveway that is 10 feet long and 10 feet wide. That specific area is one roofing square.

Now, apply this to your roof. If your roof is relatively small—say, a simple garden shed with a roof area of 500 square feet—you would divide 500 by 100.

- $500 \div 100 = 5$.

- You need 5 squares of material.

It is that simple. The shape does not dictate the square; the total area does.

Breaking Down the Bundle System

The most critical part of understanding the roofing square is knowing how it translates to the actual products you see at the hardware store. You generally cannot buy “one square” in a single package because it would be too heavy to lift.

Instead, manufacturers break a square down into bundles.

- Standard Asphalt Shingles: For most standard “3-tab” shingles, it takes three bundles to cover one square.

- Architectural Shingles: These are thicker and heavier. While many still follow the 3-bundle rule, some heavy-duty brands might require four bundles to make a square.

When you are at the store or checking a delivery, this math is vital. If your contractor says you need 10 squares, you should expect to see roughly 30 bundles of shingles sitting in your driveway.

Material Component Table

To give you a better idea of what goes into a single square, here is a breakdown of the materials typically required to cover that 100-square-foot area:

Component Typical Quantity per Square Purpose

Asphalt Shingles 3 Bundles: The main protective and aesthetic covering.

Underlayment 1/4 to 1 Roll (varies by roll size): A waterproof barrier placed directly on the wood deck.

Roofing Nails ~320 Nails (approx. 1 lb) Used to secure the shingles (generally 4 nails per shingle).

Starter Strips vary by perimeter length. Special shingles are used at the eaves and rakes to prevent wind uplift.

Understanding this breakdown helps you audit your supply list. If you are quoted for 20 squares but only see enough nails for 10, that is a red flag!

Why Use Squares?

If you are an architect or a real estate agent, you probably live and die by “square footage.” However, once you step onto a job site, “squares” become the currency of choice. But why is this distinction so important?

Several practical advantages make the “square” the superior unit of measurement for the roofing trade.

Simplicity in Quotes and Communication

Imagine a large commercial roofing project. The total surface area might be 25,000 square feet. Writing “25,000 sq ft” on every invoice, order form, and estimate sheet increases the chance of clerical errors. One missed zero could be catastrophic.

By converting this to 250 squares, the numbers become manageable. It simplifies the conversation between the homeowner and the contractor. Comparing a quote of “25 squares” versus “27 squares” is much easier for the human brain to process than comparing “2,500 sq ft” vs “2,700 sq ft.”

Standardization Across the Industry

The “square” is a universal language in the U.S. roofing industry. Whether you are talking to a supplier in New York, a contractor in Texas, or an insurance adjuster in Florida, “one square” always means 100 square feet.

This standardization ensures that when you get bids from three different companies, you can compare them apples-to-apples. If Contractor A says you need 30 squares and Contractor B says you need 45 squares, the standardized unit immediately alerts you that one of them has mismeasured your roof.

Efficiency in Ordering

As we touched on earlier, materials are packaged to fit the square system.

- Underlayment (tar paper) typically comes in rolls that cover 2 or 4 squares.

- Ice and water shield rolls often cover 1 or 2 squares.

- Shingle bundles are designed so that 3 bundles equal 1 square.

If roofers used raw square footage, they would constantly be doing complex division in their heads to figure out how many boxes of nails or rolls of paper to buy. By thinking in squares, the math for ordering becomes instant and intuitive.

Comparison: Architects vs. Roofers

It is also helpful to understand the professional divide. An architect calculates the footprint of your home (the floor area) in square feet. However, a roofer cannot use the floor plan square footage because the roof is sloped.

A house with a 2,000 sq ft floor plan might have a roof that is 2,500 to 3,000 sq ft (25 to 30 squares), depending on the slope. Using the term “squares” indicates you are referring to the actual roof surface, not the living space inside.

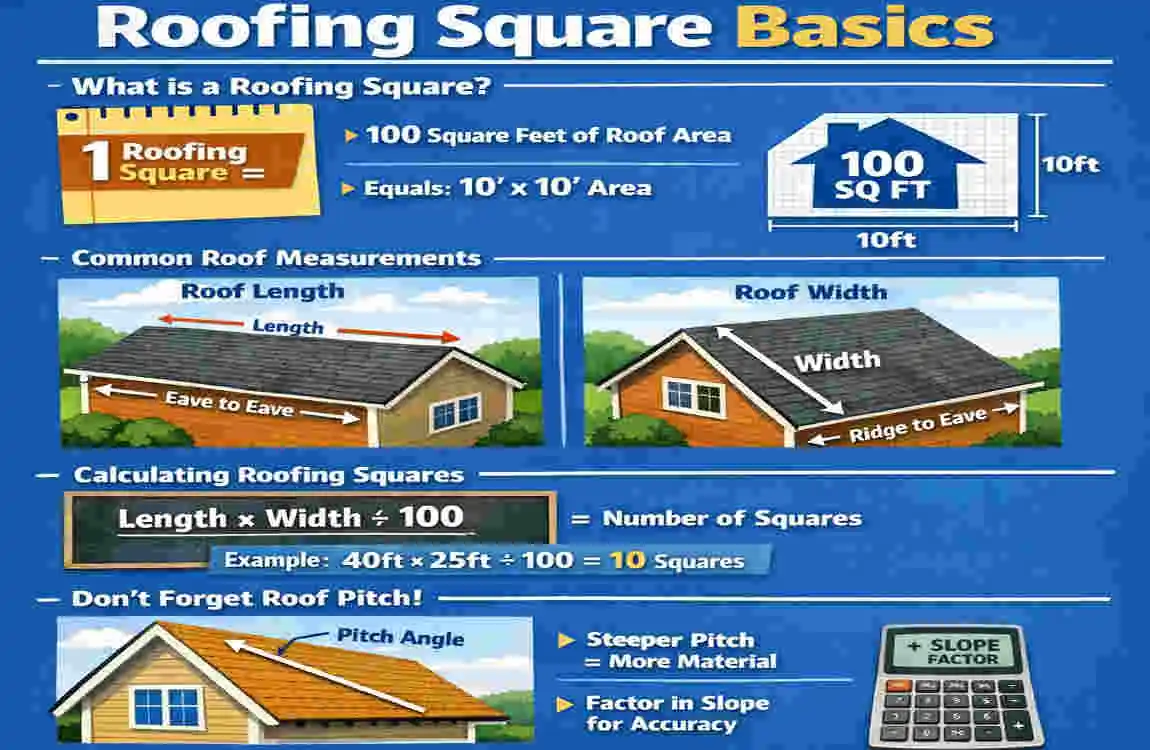

How to Calculate Roofing Squares

Now we get to the part where you can empower yourself. Calculating your own roofing needs is a great way to verify a contractor’s bid. While we always recommend a professional confirmation, a rough DIY calculation can help you avoid being scammed.

Here is a step-by-step guide to calculating the square footage of your home.

Measure the Roof Edges

First, you need to get the raw measurements. If you are comfortable climbing a ladder (and have the proper safety gear), you can measure the length and width of each plane of your roof.

If you have a simple gable roof (two sides that meet at a peak), this is easy. Measure the length of the roof (along the gutter) and the width (from the gutter to the peak).

Multiply Length $\times$ Width for each section.

- Example: 40 feet long $\times$ 20 feet wide = 800 sq ft per side.

- Two sides = 1,600 sq ft total.

Account for the Pitch (The Slope Factor)

This is where most homeowners get tripped up. If you are measuring from the ground (the house’s footprint), you are missing the extra surface area created by the roof’s slope. A steep roof has significantly more surface area than a flat roof covering the same house.

To fix this, we use a Pitch Multiplier.

- Low Pitch (4/12): Multiply flat area by ~1.05

- Medium Pitch (6/12 – 8/12): Multiply by ~1.1 to 1.2

- Steep Pitch (10/12+): Multiply by ~1.3 or more

If you measured the actual roof surface in Step 1, you can skip this. If you measured the floor footprint, you must multiply by the pitch factor.

The Formula

Once you have your total square footage (including the slope), converting to squares is the easiest part.

Formula: $$ \text{Total Square Feet} \div 100 = \text{Number of Squares} $$

- Example: If your total roof area is 1,800 sq ft.

- $1800 \div 100 = 18$ Squares.

Add the Waste Factor

You can never order exactly the amount of roof you measured. Why? Because you have to cut shingles to fit around chimneys, vents, valleys, and the edges of the roof. Once a shingle is cut, the scrap is often wasted.

You must add a waste factor to your total.

- Simple Roof (Gable): Add 5-10%.

- Complex Roof (Hips, Valleys, Dormers): Add 10-15% or more.

So, for our 18 squares example, we add 10%:

- $18 \text{ squares} \times 1.10 = 19.8 \text{ squares}$.

- Order: 20 Squares.

Example Calculation Table

Here is a quick reference guide to help you estimate based on typical roof sizes:

Roof Area (Sq Ft)Exact Squares With 10% Waste (Order Amount)

1,000 10 11 Squares

1,500 15 17 Squares

2,000 20 22 Squares

2,500 25 28 Squares

3,000 30 33 Squares

Modern Tools for Measurement

If you don’t want to climb a ladder (and we don’t blame you!), technology has made this easier.

- Google Earth: Use the measure tool to get a rough estimate of your roof’s footprint from satellite imagery.

- Drone Apps: There are smartphone apps that let you fly a camera drone over your house to generate a 3D model and perform calculations.

- Professional Reports: You can order an “EagleView” report for a small fee, which uses aerial imagery to give you exact measurements.

Materials and Costs per Square

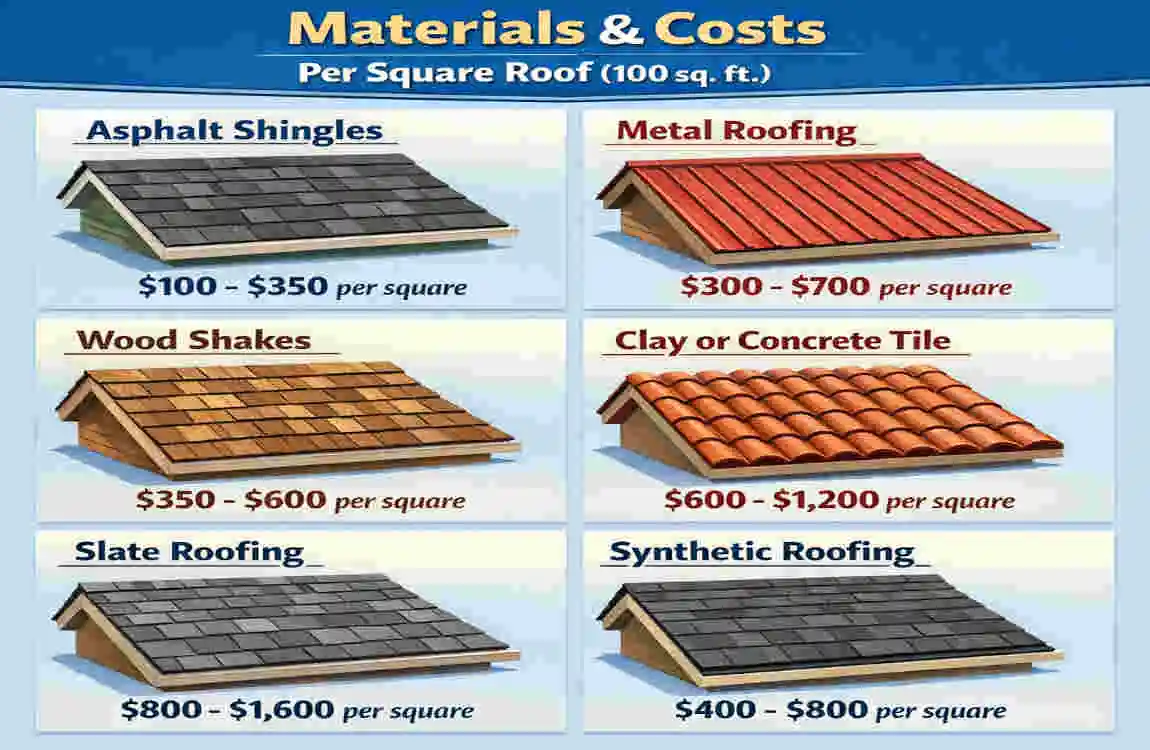

When you are budgeting, knowing the number of squares is only half the battle. You also need to know what a square costs. This varies wildly depending on the material you choose.

It is vital to distinguish between Material Cost (just the product) and Installed Cost (product + labor + overhead).

Asphalt Shingles (The Standard)

Asphalt shingles are the most common roofing material in North America.

- Material Cost: A square of standard asphalt shingles (3 bundles) typically costs between $90 and $150 at a big-box store.

- Installed Cost: When you hire a pro, you are paying for tear-off, disposal, labor, and warranty. The going rate is often $350 to $550 per square installed.

Metal Roofing

Metal is gaining popularity for its durability, but it comes at a Premium.

- Material Cost: Can range from $200 to $600 per square, depending on whether it is corrugated steel or standing seam copper.

- Installed Cost: Because metal is harder to install, labor costs soar. Expect to pay $600 to $1,200 per square installed.

Factors That Influence Cost

Why would one neighbor pay $400 a square and another pay $600 for the same shingle?

- Roof Pitch: Steep roofs require safety harnesses and slower work, increasing labor costs.

- Layers: If you have two layers of old roof to remove, the “tear-off” cost per square doubles.

- Accessibility: Can the dump truck get close to the house? If not, carrying debris by hand adds time and money.

- Region: Labor rates in a city like New York are vastly different from those in rural areas.

Material Comparison Table

Material Type Material Cost / Square Installed Cost / Square Expected Lifespan

3-Tab Asphalt $90 – $120 $350 – $450 15-20 Years

Arch. Asphalt $100 – $150 $400 – $600 20-30 Years

Metal (Steel) $200 – $400 $600 – $900 40-70 Years

Slate / Tile $500+ $1,000 – $2,000+ 50-100+ Years

Pro Tip: Always ask your contractor to break down the quote by “price per square.” This is the best way to spot if a bid is unreasonably high or worryingly low.

Common Misconceptions

Even with the definition in hand, a few myths persist. Let’s bust them to ensure you are fully informed.

A Square Must Be a Perfect Square Shape

False. We cannot stress this enough. A square is a unit of area, not geometry. You could have a long strip of roofing that is 1 foot wide and 100 feet long. That is still exactly one square. Don’t look for 10×10 boxes on your roof; look for total area.

Roofing Squares Are the Same as Flooring Squares

False. While the math (100 sq ft) is the same, the application is different. In flooring, you rarely account for “pitch.” A 100 sq ft floor is 100 sq ft. In roofing, a 100 sq ft “footprint” might actually require 130 sq ft of material due to the slope. Never use your floor plan to buy roofing materials!

If My Roof Is 20 Squares, I Buy 20 Squares

False. Remember the waste factor! If you buy exactly 20 squares, you will run out of materials before you reach the ridge cap. You always need that 10-15% buffer for cuts, mistakes, and starter rows.