Tint has become an essential element in modern automotive and architectural design. Understanding the components and types of tint can help consumers make informed decisions, whether for aesthetic or practical reasons. As we’ve explored, the materials used to create tint have evolved significantly. From simple dyes to advanced ceramic technologies, each option offers unique benefits alongside its downsides. Popular brands continue to innovate, providing products that cater to different needs and preferences. When choosing between DIY installations and professional services, it’s important to weigh factors like skill level, cost-effectiveness, and desired outcomes. Proper care ensures longevity for your tinted windows while being mindful of environmental implications, which remains crucial as we navigate more sustainable practices within industry production.

The History and Evolution of Tint

Tinting has a fascinating history that traces back thousands of years. Ancient civilizations like the Egyptians and Romans experimented with colored glass to enhance aesthetics and limit sunlight exposure. In the 1960s, automotive tints became popular due to rising temperatures and increased car ownership. Drivers sought relief from glare while adding a stylish touch to their vehicles. Throughout the decades, advancements in technology transformed tint production. The introduction of synthetic dyes and metals improved durability and effectiveness. Innovations have also made it easier for consumers to choose tints based on personal preference.

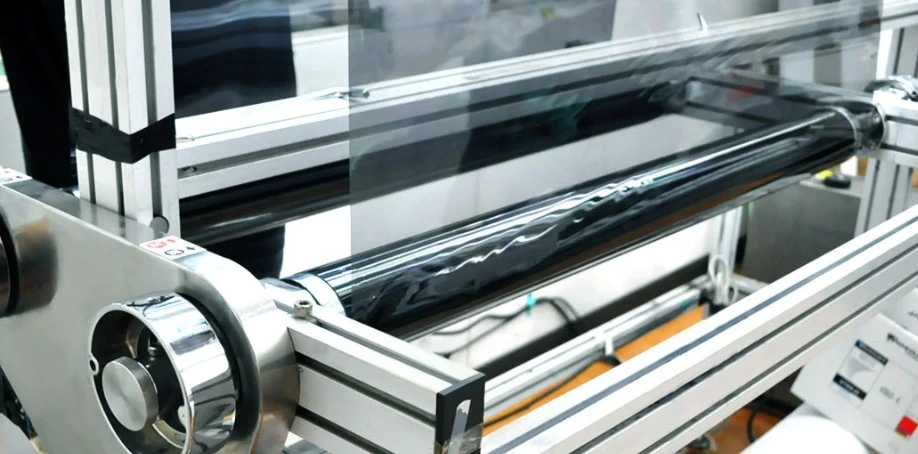

Common Materials Used in Tint Production

Tint production utilizes various materials, each contributing to the final product’s performance and appearance. Polyester film is one of the most common components, known for its durability and scratch resistance. This material forms the base layer of many window films. Dyes play a crucial role as well. They are often added to tint films to provide color while absorbing heat from sunlight. The quality of dyes can impact both longevity and fade resistance. Metalized films incorporate tiny metal particles that enhance reflectivity. These metals help reduce glare and improve energy efficiency within vehicles or buildings. Ceramic tints have gained popularity due to their unique composition. Made with advanced nanotechnology, they offer superior UV protection without compromising visibility.

Types of Tint: Dye, Metalized and Ceramic

There are three main types of window tint: dye, metalized, and ceramic. Each has its unique characteristics and benefits. Dye-based tints infuse color into the film itself. They offer a variety of shades but can fade over time with exposure to sunlight. This type is often more affordable but may provide less heat rejection. Small metallic particles are contained in metalized tints that reflect UV rays and heat.They deliver excellent privacy while enhancing durability. They can interfere with electronic signals like GPS or mobile reception. Ceramic tints utilize advanced technology without any metals or dyes. This makes them highly effective at blocking heat while maintaining clarity and visibility. Pricier than other types, their longevity and performance make them worth considering for many consumers.

Advantages and Disadvantages of Different Types of Tint

Each type of tint comes with its own set of pros and cons. Dye-based tints are popular for their rich colors and affordability. They tend to fade over time when exposed to sunlight. Metalized tints offer better heat rejection and durability. The metallic particles reflect UV rays effectively. Yet, they can interfere with electronic devices like GPS or mobile signals. Ceramic tints stand out for their exceptional performance without signal disruption. They provide excellent heat reduction while maintaining clarity. On the downside, they often come at a higher price than other types.

Popular Brands and Products Using Tint

Regarding window tinting, several brands stand out in the market for their quality and innovation. 3M is a leader known for its advanced technology. Their products provide excellent heat rejection and UV protection. Another strong contender is Llumar, which offers a range of tints suitable for different needs. From residential to automotive applications, they emphasize durability and aesthetics. Solar Gard also deserves mention for its eco-friendly options that combine performance and sustainability. Their films are designed to enhance comfort while minimizing energy consumption. For those seeking luxury finishes, Huper Optik presents premium ceramic films renowned for their clarity and efficiency without compromising appearance.

DIY vs Professional Installation

When tinting your windows, you face a choice: DIY or professional installation. Both options have their merits and drawbacks. DIY installations can save you money. With the right tools and materials, you can tackle the project yourself. You can find plenty of tutorials online that will guide you step-by-step through the process. In spite of this, achieving a flawless finish can be challenging. Bubble formation or misalignment mar your hard work. Professionals bring expertise to the table. They understand techniques that ensure an even application without imperfections. Their experience often translates into quicker results, too. Hiring experts typically cost more upfront. It’s essential to weigh your budget against the desired quality before deciding on this route. Choosing DIY or enlisting professional help depends on your confidence in tackling such projects and how much you’re willing to invest for pristine results.

Proper Care and Maintenance of Tinted Windows

Maintaining tinted windows is essential to ensure their longevity and performance. Start by avoiding harsh chemicals when cleaning. Instead, use a gentle soap solution or a specialized window cleaner for tints. Microfiber clothes are your best friend here. They prevent scratches while effectively lifting dirt and grime without damaging the tint’s surface. Always wipe gently in circular motions to avoid streaks. It’s also important to wait 30 days after installation before applying any cleaners. This allows the adhesive to cure properly, ensuring that your tint adheres well over time.

Environmental Impact of Tint Production

The production of window tint involves various materials, some of which can have significant environmental implications. Many tints are made from plastics and films that require energy-intensive processes to manufacture. These methods often contribute to greenhouse gas emissions. The chemicals used in dyeing and coating tints can pose risks if not managed properly. Some substances may leach into water systems during manufacturing or disposal, raising concerns about pollution. On a positive note, technological advancements are leading to more eco-friendly alternatives. Manufacturers are increasingly exploring sustainable materials that reduce the ecological footprint of their products. Consumers must be aware of these impacts when choosing tint options. Selecting brands committed to sustainability can make a meaningful difference in mitigating harm to our planet while enjoying the benefits of window film.